(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- Due to ongoing conflict at the Indian borders, shipment delivery lead times to impacted areas may be affected.

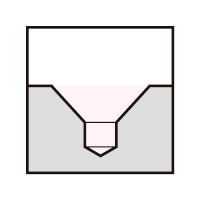

Chamfering / Centering Tools

Chamfering/countersinking tools are tools used for grinding center holes, positioning holes, grinding holes, or deburring and rounding the edges after side-surface machining. They are attached to machine tools such as drill press, lathe, machining center, etc. Center drills are used to position the initial indentatio

Chamfering/countersinking tools are tools used for grinding center holes, positioning holes, grinding holes, or deburring and rounding the edges after side-surface machining. They are attached to machine tools such as drill press, lathe, machining center, etc. Center drills are used to position the initial indentation on the work material to avoid misalignment of the drill bit tip. Their materials include alloy carbide, powdered high-speed steel, cobalt high-speed steel and high-speed steel. Countersinking and chamfering cutters are capable of chamfering after drilling holes. Chamfering cutters with a hole on the tip allow for smooth cutting discharge on soft work materials such as copper and aluminum. Center drills have a 90° tip angle and they can be used for positioning and chamfering at the same time.

Search by specifying the lower class category

Centering/Countersink

Centering/Countersink Chamfer, V-Grooves

Chamfer, V-Grooves Inner R

Inner R Replaceable Blade Type Chamfering Tools/Tips/Blades

Replaceable Blade Type Chamfering Tools/Tips/Blades

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

423 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Back Seat Mini Chamfer (90° Blade)

NOGA JAPAN

New at MISUMI? Get 20% Discount on your First Purchase. Click to Register Now

[Features]

·A solid carbide chamfering cutter that can chamfer the back of small holes (minimum cutting edge diameter 1.5 mm).

·Perfect for machining.

·Can be used for milling, deburring, and back chamfering.

·The spiral blade provides a smooth cutting edge.

·This is a mini chamfer that can be chamfered and deburred by milling both the front and back of drilled holes.

[Applications]

·Work Material: Carbon steel, stainless steel, cast steel, aluminum, plastic, nickel alloy, titanium alloy, etc.

·A mini chamfer that can be chamfered and deburred by milling both the front and back of drilled holes.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - 1.5 ~ 6 90 - - - - - TiAlN - From: ₹ 5,924.49 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

SANKO MFG

New at MISUMI? Get 20% Discount on your First Purchase. Click to Register Now

A cutter dedicated to curved surface chamfering.

Work Material, Carbon Steel, Steel Alloy, Tool Steel/Cast Iron

Tool Grade, Cobalt High-Speed SteelTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 9 ~ 32 - Round Chamfer general steel[○] / Cast Iron[○] - NA NA Non-Coated 0.5 ~ 10 From: ₹ 4,410.98 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Nine9

New at MISUMI? Get 20% Discount on your First Purchase. Click to Register Now

The special insert design realizes an ultra-long operating life.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.45~2.1 ~ 0.65~2.7 45 ~ 60 Centering (Positioning) / Engraved general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○/◎] / Cast Iron[○/◎] / Aluminum[○/◎] / Titanium[○] / Copper[○] / Resin[○] Single blade NA Available TiAlN / TiN - From: ₹ 3,639.69 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Nine9

Insert for NC spot drill holder.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1–6 ~ 3 to 15 60 ~ 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Engraved general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○/◎] / Cast Iron[○/◎] / Aluminum[○] / Titanium[○] / Copper[○] / Resin[○] Single blade NA Available TiAlN / TiN / DLC - From: ₹ 3,043.65 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

MUGEN-COATING 2-Flute Inner Radius Cutter MIR200

NS TOOL

Supports NCs and MCs. R chamfering can be easily machined. Infinity coating used for significantly greater durability

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.8 ~ 12.1 - Round Chamfer general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[◎] / Stainless Steel[◎] / Aluminum[◎] / Titanium[○] / Copper[◎] / Resin[◎] - - Available TiAlN 0.1 ~ 5 From: ₹ 5,292.27 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

High-Speed Steel Center Drill, Regular / New JIS, Model A

MISUMI

New at MISUMI? Get 20% Discount on your First Purchase. Click to Register Now

[Features]

·Necessary items for positioning processing

·Non-coated high-speed steel double-edged 2-flute tip angle 120° type (New JIS A type)Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1 ~ 5 - Centering (Positioning) general steel[○] Double-edged NA NA - - From: ₹ 259.00 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

BIG DAISHOWA SEIKI

[Features]

· Aggregation of chamfering tools is enabled with the C-Cutter, suitable for a wide range of applications.

· A dedicated design for chamfering, this insert has a large rake angle and provides beautiful chamfering.

· The wide machining range can reduce the number of tools inside the magazine to greatly improve the ATC loss time.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - 5~85 ~ 60 Chamfering/Horizontal - - NA - - - From: ₹ 10,074.38 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Submarine Gate Cutter, 20°, 30°_CS-G

YAMAWA MFG

A specialized drill for use when machining submarine gates (tunnel gates) in the dies used for plastic injection molding.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 6 ~ 8 30 Other - Single blade NA NA - - From: ₹ 2,102.82 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

FUKUDA

New at MISUMI? Get 20% Discount on your First Purchase. Click to Register Now

End mill for R chamfering.

[Features]

·The use of a straight blade makes it easy to re-grind and has excellent cost performance.

·The shank diameter is designed to be thick, making it rigid.

·A rich lineup from R0.5 to 30.

[Applications]

·Ideal for R chamfering.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel - - Round Chamfer general steel[○] / Cast Iron[○] / Resin[○] Single blade NA NA Non-Coated 0.5 ~ 30 From: ₹ 5,768.05 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

HSS Center Drill, A Type, 60°, TiCN Coating

IWATA TOOL

[Features]

· A center drill with high sharpness and outstanding durability.

· Iwata Tool's center drills never stop evolving.

· In addition to improving runout accuracy, the use of cobalt HSS and an optimized tool shape deliver excellent sharpness and help prevent breakages.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 0.5 ~ 5 60 Centering (Positioning) general steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Double-edged NA Available TiCN - From: ₹ 1,762.62 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide Center Drill Bit, A Type 60°

IWATA TOOL

New at MISUMI? Get 20% Discount on your First Purchase. Click to Register Now

[Features]

· The carbide material supporting various machining is tougher and the shape is optimized, drastically reducing breakage issues.

· Speed can be enhanced and life can be extended.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 8 60 Centering (Positioning) general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] / Resin[○] Double-edged NA NA - - From: ₹ 3,786.44 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

C-Cutter Mini, Multi-Flute Front/Back-Chamfering Type

BIG DAISHOWA SEIKI

[Features]

· Multiple-flute type front and back chamfering "C-Cutter Mini" high performance chamfering cutter that achieves ultra-high feed rates and a compact size.

· Ultra-high feed machining achieves dramatic reductions in chamfering time.

· Supports a wide range of machining, such as front chamfering, back chamfering, and face milling.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - 45° Hole Chamfer - - NA - - - From: ₹ 13,484.47 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

EIKOSHA

[Features]

· Capable of centering, chamfering and side machining, as well as drilling and V grooving depending on the tip angle.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 4 ~ 35 30 ~ 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove general steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] - - NA - - From: ₹ 5,465.36 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Counter Sink (For Outer Diameter Chamfering)

NOGA JAPAN

[Features]

· KOPAL chamfer unit is made of a combination of a body, blade, and guide.

· Conical guide serves to align the workpiece, and its height can be adjusted with a spring.

· HSS steel blade can be locked with a nut to set the blade projection length.

[Applications]

· Outer diameter chamfering.

· For chamfering end faces of round bars, square rods, etc.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - - - - - - - - - From: ₹ 23,234.35 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Counter Sink (For Inner and Outer Diameter Chamfering)

NOGA JAPAN

New at MISUMI? Get 20% Discount on your First Purchase. Click to Register Now

[Features]

· Simultaneous chamfering of pipe inner/outer sides is possible, with each individually configured.

· KOPAL chamfer unit is made of a combination of a body, blade, and guide.

· Conical guide serves to align the workpiece, and its height can be adjusted with a spring.

· HSS steel blade can be locked with a nut to set the blade projection length.

[Applications]

· Internal and external chamfering.

· Simultaneous chamfering of pipe inner/outer sides.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - - - - - - - - - From: ₹ 75,179.20 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

FUKUDA

A cutting tool used for finishing the center hole and chamfering.

[Features]

·Because it is designed with an odd number of flutes, machining with little chatter is possible.

·A rich lineup of 60°, 90° and 120°.

[Applications]

·Ideal for finishing center holes, as well as chamfering corners.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel - 60 ~ 120 Hole Chamfer general steel[○] / Quenched and tempered steel[○] / Cast Iron[○] / Aluminum[○] / Resin[○] Single blade NA NA Non-Coated - From: ₹ 1,984.75 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide 2-Flute Chamfering V-Grooving End Mill 90° E107X

7 LEADERS

[Features]

· 90° Carbide 2-Flute Chamfering V-Grooving End Mill

· Use for V-grooving, horizontal chamfering, centering, hole chamfering.

· Nanoparticle Multilayer Coating

· Excellent lubricity and abrasion resistance.

· Suitable for a wide range of work materials from general steel to aluminum.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.5 ~ 20 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] / Resin[○] - - Available Other - From: ₹ 3,151.56 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiN-Coated High-Speed Steel Center Drill, Regular Model

MISUMI

Frequently used standard sizes are offered at affordable prices

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1 ~ 4 - Centering (Positioning) general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Double-edged NA Available TiN - From: ₹ 740.00 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

FUKUDA

A single product capable of five types of machining: center positioning, chamfering, side surface machining, drilling, and V-grooving.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 4 ~ 40 60 ~ 120 Centering (Positioning) / Hole Chamfer / V Groove / Drilling / Other general steel[○] / Cast Iron[○] / Resin[○] Single blade Available NA Non-Coated - From: ₹ 4,475.55 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Corner Radius Cutter Carbide for Aluminum

IWATA TOOL

[Features]

· The raking blades/flutes ensure a highly precise rounded form.

· First-ever large rake angle for round chamfering tools, dramatically improved sharpness/surface roughness, significantly reduced cutting heat, and improved runout accuracyTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 5 - Round Chamfer general steel[○] / Quenched and tempered steel[○] / Aluminum[○] / Copper[○] / Resin[○] Single blade NA NA - 0.5 ~ 3 From: ₹ 6,434.42 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide Center Drill Bit, B-Type, ALD Coating

IWATA TOOL

[Features]

· The carbide material supporting various machining is tougher and the shape is optimized, drastically reducing breakage issues.

· Speed can be enhanced and life can be extended.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 6.3 60 Centering (Positioning) general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Double-edged NA Available Other - From: ₹ 7,207.25 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

BIG DAISHOWA SEIKI

[Features]

・ Ideal for chamfering work on a desktop drill press

・ Carbide throw-away insert enables clean chamfering

・ Carbide guide prevents chattering, anyone can work easilyTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - 45 Chamfering/Horizontal general steel[○] / Cast Iron[○] / Aluminum[○] - NA - - - From: ₹ 15,239.09 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Chamfering Cutter (for Spool Bushing) RC

EIKOSHA

[Features]

· For mold nozzle arrays machining.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS - - Round Chamfer general steel[○] / Aluminum[○] / Copper[○] - - NA - 10.5 ~ 20.5 From: ₹ 9,035.93 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Long Reach Back Spot Facing Mini Chamfer 90° Blade (for deep holes)

NOGA JAPAN

[Features]

· A solid carbide chamfering cutter which can chamfer small diameter hole backs (minimum blade diameter: 3.0 mm).

· Ideal for machining.

· Spiral blade provides smooth sharpness.

· A mini chamfer that can chamfer/deburr by milling either the back or front of the drill hole.

[Applications]

· Work materials: Carbon steel, stainless steel, cast steel, aluminum, plastic, nickel alloy, titanium alloy, etc.

· A mini chamfer that can chamfer and deburr by milling either the back or front of the drill hole.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - 3 ~ 12 90 - - - - - TiAlN - From: ₹ 6,024.95 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 90°

MAKOTOLOY

New at MISUMI? Get 20% Discount on your First Purchase. Click to Register Now

[Features]

· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.

· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.

· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.

· An ultra-fine particle carbide alloy is used for the carbide material.

· Long tool life, improved cutting speed and reduced machining time.

· Standard type.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 20 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: ₹ 11,203.09 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiN Coated / Non-Coated High-Speed Steel NC Spot Drill

MISUMI

Long service life that's made possible by the coating technology. Ideal for Hole Chamfering and Centering

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 2 ~ 20 90 ~ 120 Centering (Positioning) / Hole Chamfer general steel[○/◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Aluminum[○] / Copper[○] Single blade NA Available / NA TiN / Non-Coated - From: ₹ 407.00 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

OSG

TiN coating enables higher speed and longer service life compared to NC-LDS

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 3 ~ 25 60 ~ 120 Centering (Positioning) / Hole Chamfer general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[◎] / Titanium[◎] / Copper[◎] Single blade NA Available TiN - From: ₹ 1,437.53 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

OSG

V coating enables longer service life compared to TIN-NC-LDS

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Powder high-speed steel 3 ~ 25 90 Centering (Positioning) / Hole Chamfer general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Titanium[◎] / Copper[◎] Single blade NA Available TiCN - From: ₹ 1,839.35 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

3-flute Chamfering Cutter (positive type) HSCT-P

OSG

End mill for positive type chamfering. It suppresses chattering during processing and has good chip removal capability for a beautiful finished surface.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 2 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove general steel[○] / Stainless Steel[◎] / Aluminum[◎] / Titanium[◎] Single blade NA NA Non-Coated - From: ₹ 8,228.25 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

VP-LS-LDS Hole Chamfering, Leading Drill, V Coating Powder High-speed Steel Long Shank

OSG

Leading drill long shank type, using powder metal high-speed steel XPM as the base material, with 90° of the V coated tip angle. Ideal for chamfering deep parts.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Powder high-speed steel 3 ~ 25 90 Centering (Positioning) / Hole Chamfer general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] Single blade Available Available TiCN - From: ₹ 2,499.65 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

EIKOSHA

Center Positioning, Plate/Internal Chamfering, External Chamfering

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 10 ~ 32 90 ~ 118 Centering (Positioning) / Chamfering/Horizontal general steel[○] / Quenched and tempered steel[○] / Aluminum[○] / Copper[○] - - - - - From: ₹ 9,387.49 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NC Spot Drill / Corner Radius Cutter for 90°

Nine9

Carbide insert type NC spot drill. High efficiency! Low cost! Ideal for CNC lathes and machining centers. Inserts that can process corner radii can also be used.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - 16 ~ 20 90 Centering (Positioning) / Hole Chamfer - Single blade NA NA Non-Coated - From: ₹ 12,668.75 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NC Spot Drill / Carving Cutter for 90°

Nine9

Carbide insert type NC spot drill. High efficiency! Low cost! Ideal for CNC lathes and machining centers. Inserts for engraving cutters can also be used.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - 10 90 Centering (Positioning) / Hole Chamfer - Single blade NA NA Non-Coated - From: ₹ 11,208.47 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

HSS, Center Drill Bit Long, A Type 90°

IWATA TOOL

[Features]

· A center drill with high sharpness and outstanding durability.

· Iwata Tool's center drills never stop evolving.

· In addition to improving runout accuracy, the use of cobalt HSS and an optimized tool shape deliver excellent sharpness and help prevent breakages.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 0.8 ~ 6 90 Centering (Positioning) general steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] / Resin[○] Double-edged NA NA - - From: ₹ 2,329.18 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Center Drill, Okabe Standard, Type 1, Carbide 60°

OKABE

Because it uses carbide materials, it has both high hardness and elasticity. It is a center drill manufactured with one of the best heat treatment, and can be used for machining general steel, heat-treated steel, stainless steel, cast iron, etc.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.3 ~ 6 60 Centering (Positioning) general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] Single blade / Double-edged NA NA Non-Coated - From: ₹ 9,260.55 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Throw-away Tip for C-Cutter Mini

BIG DAISHOWA SEIKI

Throw-away insert for "C-Cutter Mini" high performance chamfering cutters that achieve ultra-high feed rates and a compact size.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - - Hole Chamfer / Chamfering/Horizontal general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] - - Available Other 0.2 From: ₹ 1,577.00 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

High Speed Chamfering Tool TOGLON® Multi Chamfer

IWATA TOOL

New at MISUMI? Get 20% Discount on your First Purchase. Click to Register Now

[Features]

· Toglon-shaped 5-flute chamfering dedicated model

· Ultra-high speed machining with suppressed burrs is possible for light chamfering

[Applications]

· Work materials: Mild steel, carbon steel, alloy steel, tempered steel, stainless steel, titanium alloyTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - 90 - - - - - Non-Coated / ALT - From: ₹ 4,136.40 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Chamfering cutter, C cutter, universal type

BIG DAISHOWA SEIKI

[Features]

・ Chamfering angle of 5° to 85° is available with this one

・ It can rotate with a wrench to swing the cartridge and adjust the chamfer angle

[Applications]

・ Work material: Steel, cast iron, aluminumTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - 5~85° - - - - - - - From: ₹ 45,788.87 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

ATI

[Features]

· NATO stock number acquired.

· Achieves high concentricity due to shaving machining.

· M2 HSS steel is adopted to achieve excellent sharpness, high hardness, and wear resistance.

· To be mounted to micro stops.

[Flute No.]

· ATI420D: 3

· ATI445E: 2

[Applications]

· For aircraft MRO.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - Cutter Tip Angle: 100° - - - - - - - From: ₹ 1,673.25 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TS coated carbide inner R-cutter, 2-flute

MISUMI

[Features]

·Easy high-quality processing of corner radius

·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties- TS

- General Steel

- 2 Flutes

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide - - Round Chamfer general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade NA Available TS 0.1 ~ 5 From: ₹ 2,845.24 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiCN Coated Powdered High-Speed Steel Chamfering End Mill, 2-Flute, Short

MISUMI

The chamfer angle can be selected from 60, 90 and 120°according to the machining style

- TiCN

- 2 Flutes

- S (Short)

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Powder high-speed steel 10 ~ 25 60 ~ 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade Available Available - - From: ₹ 3,281.98 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

MISUMI

The non-coated design allows the edge of the tip to stand, achieving the high cut-off performance.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.3 ~ 2 - Centering (Positioning) / Hole Chamfer general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] Single blade NA NA - - From: ₹ 3,648.20 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated High-Speed Steel Countersink, 1-Flute / 90°

MISUMI

1-flute type with high versatility in countersink

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 10 ~ 25 - Hole Chamfer general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade NA Available TiAlN - From: ₹ 1,672.40 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiN-Coated High-Speed Steel Countersink, with Holes / 90°

MISUMI

Frequently used standard sizes are offered at affordable prices

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 10 ~ 35 - Hole Chamfer general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade NA Available TiN - From: ₹ 1,071.17 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Nine9

An innovative carbide insert type engraving tool. High-quality engraving is possible on most material.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - 6 45 Other - Single blade NA NA Non-Coated - From: ₹ 9,730.24 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Specifications |

| Tool Material Type |

| Tool Diameter (D)(mm) |

| Tip angle (θ) |

| Application |

| work material |

| Single blade, two blades |

| Peripheral Blade Y/N |

| Coating Y/N |

| Coating Type |

| R Size (R)(mm) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | NOGA JAPAN | SANKO MFG | Nine9 | Nine9 | NS TOOL | MISUMI | BIG DAISHOWA SEIKI | YAMAWA MFG | FUKUDA | IWATA TOOL | IWATA TOOL | BIG DAISHOWA SEIKI | EIKOSHA | NOGA JAPAN | NOGA JAPAN | FUKUDA | 7 LEADERS | MISUMI | FUKUDA | IWATA TOOL | IWATA TOOL | BIG DAISHOWA SEIKI | EIKOSHA | NOGA JAPAN | MAKOTOLOY | MISUMI | OSG | OSG | OSG | OSG | EIKOSHA | Nine9 | Nine9 | IWATA TOOL | OKABE | BIG DAISHOWA SEIKI | IWATA TOOL | BIG DAISHOWA SEIKI | ATI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | Nine9 |

| Product Series | Long Reach Back Spot Facing Mini Chamfer 90° Blade (for deep holes) | V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 90° | VP-LS-LDS Hole Chamfering, Leading Drill, V Coating Powder High-speed Steel Long Shank | TiCN Coated Powdered High-Speed Steel Chamfering End Mill, 2-Flute, Short | |||||||||||||||||||||||||||||||||||||||||

| CAD |

|

|

|

|

|

| |||||||||||||||||||||||||||||||||||||||

| From | ₹ 5,924.49 | ₹ 4,410.98 | ₹ 3,639.69 | ₹ 3,043.65 | ₹ 5,292.27 | ₹ 259.00 | ₹ 10,074.38 | ₹ 2,102.82 | ₹ 5,768.05 | ₹ 1,762.62 | ₹ 3,786.44 | ₹ 13,484.47 | ₹ 5,465.36 | ₹ 23,234.35 | ₹ 75,179.20 | ₹ 1,984.75 | ₹ 3,151.56 | ₹ 740.00 | ₹ 4,475.55 | ₹ 6,434.42 | ₹ 7,207.25 | ₹ 15,239.09 | ₹ 9,035.93 | ₹ 6,024.95 | ₹ 11,203.09 | ₹ 407.00 | ₹ 1,437.53 | ₹ 1,839.35 | ₹ 8,228.25 | ₹ 2,499.65 | ₹ 9,387.49 | ₹ 12,668.75 | ₹ 11,208.47 | ₹ 2,329.18 | ₹ 9,260.55 | ₹ 1,577.00 | ₹ 4,136.40 | ₹ 45,788.87 | ₹ 1,673.25 | ₹ 2,845.24 | ₹ 3,281.98 | ₹ 3,648.20 | ₹ 1,672.40 | ₹ 1,071.17 | ₹ 9,730.24 |

| Days to Ship | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 6 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 6 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 7 Day(s) or more | 6 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 6 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 5 Day(s) or more |

| Specifications |

|

| |||||||||||||||||||||||||||||||||||||||||||

| Tool Material Type | - | Cobalt HSS | Carbide | Carbide | Carbide | High-speed steel | - | High-speed steel | High-speed steel | High-speed steel | Carbide | - | Cobalt HSS | - | - | High-speed steel | Carbide | High-speed steel | Cobalt HSS | Carbide | Carbide | - | Cobalt HSS | - | Carbide | Cobalt HSS | High-speed steel | Powder high-speed steel | Carbide | Powder high-speed steel | Cobalt HSS | - | - | High-speed steel | Carbide | - | - | - | - | Carbide | Powder high-speed steel | Carbide | Cobalt HSS | Cobalt HSS | - |

| Tool Diameter (D)(mm) | 1.5 ~ 6 | 9 ~ 32 | 0.45~2.1 ~ 0.65~2.7 | 1–6 ~ 3 to 15 | 0.8 ~ 12.1 | 1 ~ 5 | - | 6 ~ 8 | - | 0.5 ~ 5 | 1 ~ 8 | - | 4 ~ 35 | - | - | - | 0.5 ~ 20 | 1 ~ 4 | 4 ~ 40 | 3 ~ 5 | 1 ~ 6.3 | - | - | 3 ~ 12 | 1 ~ 20 | 2 ~ 20 | 3 ~ 25 | 3 ~ 25 | 1 ~ 2 | 3 ~ 25 | 10 ~ 32 | 16 ~ 20 | 10 | 0.8 ~ 6 | 0.3 ~ 6 | - | - | - | - | - | 10 ~ 25 | 0.3 ~ 2 | 10 ~ 25 | 10 ~ 35 | 6 |

| Tip angle (θ) | 90 | - | 45 ~ 60 | 60 ~ 90 | - | - | 5~85 ~ 60 | 30 | - | 60 | 60 | 45° | 30 ~ 120 | - | - | 60 ~ 120 | 90 | - | 60 ~ 120 | - | 60 | 45 | - | 90 | 90 | 90 ~ 120 | 60 ~ 120 | 90 | 90 | 90 | 90 ~ 118 | 90 | 90 | 90 | 60 | - | 90 | 5~85° | Cutter Tip Angle: 100° | - | 60 ~ 120 | - | - | - | 45 |

| Application | - | Round Chamfer | Centering (Positioning) / Engraved | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Engraved | Round Chamfer | Centering (Positioning) | Chamfering/Horizontal | Other | Round Chamfer | Centering (Positioning) | Centering (Positioning) | Hole Chamfer | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove | - | - | Hole Chamfer | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove | Centering (Positioning) | Centering (Positioning) / Hole Chamfer / V Groove / Drilling / Other | Round Chamfer | Centering (Positioning) | Chamfering/Horizontal | Round Chamfer | - | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) | Centering (Positioning) | Hole Chamfer / Chamfering/Horizontal | - | - | - | Round Chamfer | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer | Hole Chamfer | Hole Chamfer | Other |

| work material | - | general steel[○] / Cast Iron[○] | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○/◎] / Cast Iron[○/◎] / Aluminum[○/◎] / Titanium[○] / Copper[○] / Resin[○] | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○/◎] / Cast Iron[○/◎] / Aluminum[○] / Titanium[○] / Copper[○] / Resin[○] | general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[◎] / Stainless Steel[◎] / Aluminum[◎] / Titanium[○] / Copper[◎] / Resin[◎] | general steel[○] | - | - | general steel[○] / Cast Iron[○] / Resin[○] | general steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] / Resin[○] | - | general steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | - | - | general steel[○] / Quenched and tempered steel[○] / Cast Iron[○] / Aluminum[○] / Resin[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] / Resin[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[○] / Cast Iron[○] / Resin[○] | general steel[○] / Quenched and tempered steel[○] / Aluminum[○] / Copper[○] / Resin[○] | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Aluminum[○] / Copper[○] | - | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○/◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[◎] / Titanium[◎] / Copper[◎] | general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Titanium[◎] / Copper[◎] | general steel[○] / Stainless Steel[◎] / Aluminum[◎] / Titanium[◎] | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] | general steel[○] / Quenched and tempered steel[○] / Aluminum[○] / Copper[○] | - | - | general steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] / Resin[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | - | - | - | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] | general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | - |

| Single blade, two blades | - | - | Single blade | Single blade | - | Double-edged | - | Single blade | Single blade | Double-edged | Double-edged | - | - | - | - | Single blade | - | Double-edged | Single blade | Single blade | Double-edged | - | - | - | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | - | Single blade | Single blade | Double-edged | Single blade / Double-edged | - | - | - | - | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade |

| Peripheral Blade Y/N | - | NA | NA | NA | - | NA | NA | NA | NA | NA | NA | NA | - | - | - | NA | - | NA | Available | NA | NA | NA | - | - | - | NA | NA | NA | NA | Available | - | NA | NA | NA | NA | - | - | - | - | NA | Available | NA | NA | NA | NA |

| Coating Y/N | - | NA | Available | Available | Available | NA | - | NA | NA | Available | NA | - | NA | - | - | NA | Available | Available | NA | NA | Available | - | NA | - | Available | Available / NA | Available | Available | NA | Available | - | NA | NA | NA | NA | Available | - | - | - | Available | Available | NA | Available | Available | NA |

| Coating Type | TiAlN | Non-Coated | TiAlN / TiN | TiAlN / TiN / DLC | TiAlN | - | - | - | Non-Coated | TiCN | - | - | - | - | - | Non-Coated | Other | TiN | Non-Coated | - | Other | - | - | TiAlN | TiAlN | TiN / Non-Coated | TiN | TiCN | Non-Coated | TiCN | - | Non-Coated | Non-Coated | - | Non-Coated | Other | Non-Coated / ALT | - | - | TS | - | - | TiAlN | TiN | Non-Coated |

| R Size (R)(mm) | - | 0.5 ~ 10 | - | - | 0.1 ~ 5 | - | - | - | 0.5 ~ 30 | - | - | - | - | - | - | - | - | - | - | 0.5 ~ 3 | - | - | 10.5 ~ 20.5 | - | - | - | - | - | - | - | - | - | - | - | - | 0.2 | - | - | - | 0.1 ~ 5 | - | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Tool Material Type

-

Tool Diameter (D)(mm)

- 0 to 2

- 0.02

- 0.03

- 0.04

- 0.05

- 0.06

- 0.07

- 0.08

- 0.09

- 0.1

- 0.11

- 0.12

- 0.13

- 0.14

- 0.15

- 0.16

- 0.17

- 0.18

- 0.19

- 0.2

- 0.21

- 0.22

- 0.23

- 0.24

- 0.25

- 0.26

- 0.27

- 0.28

- 0.29

- 0.3

- 0.3, 0.6

- 0.35

- 0.4

- 0.45

- 0.45~2.1

- 0.45~2.7

- 0.5

- 0.5, 1

- 0.55

- 0.6

- 0.65

- 0.65~2.1

- 0.65~2.7

- 0.7

- 0.75

- 0.8

- 0.85

- 0.9

- 0.95

- 1

- 1, 2

- 1–6

- 1/8

- 1/16

- 1/32

- 1/64

- 1.1

- 1.2

- 1.25

- 1.3

- 1.4

- 1.5

- 1.6

- 1.7

- 1.8

- 1.9

- 2.

- 2

- 2–10

- 2~13

- 2.1

- 2.2

- 2.3

- 2.4

- 2.5

- 2.6

- 2.7

- 2.8

- 2.9

- 3

- 3~14

- 3 to 15

- 3/16

- 3/32

- 3/64

- 3.1

- 3.15

- 3.2

- 3.4

- 3.5

- 3.6

- 3.8

- 4

- 4.2

- 4.3

- 4.4

- 4.5

- 4.6

- 4.8

- 5

- 5/16

- 5/32

- 5/64

- 5.1

- 5.2

- 5.3

- 5.4

- 5.5

- 5.6

- 5.8

- 6

- 6.2

- 6.3

- 6.3,8.3,10.4,12.4,16.5,20.5

- 6.30/8.30/10.40/12.40/16.50/20.50

- 6.3/8.3/10.4/12.4/16.5/20.5

- 6.35

- 6.4

- 6.5

- 6.6

- 6.8

- 7

- 7.2

- 7.3

- 7.4

- 7.5

- 7.6

- 7.7

- 7.8

- 8

- 8.2

- 8.3

- 8.4

- 8.8

- 9

- 9.1

- 9.4

- 9.5

- 9.52

- 10

- 10.1

- 10.3

- 10.4

- 10.5

- 10.8

- 11

- 11.1

- 11.4

- 11.5

- 11.88

- 12

- 12.1

- 12.3

- 12.4

- 12.5

- 12.7

- 13

- 13.4

- 13.5

- 14

- 14.2

- 14.4

- 14.5

- 14.6

- 15

- 15.1

- 15.2

- 15.4

- 15.5

- 15.6

- 15.87

- 16

- 16.15

- 16.3

- 16.5

- 16.5,20.5,25.0,37.0

- 17

- 17.1

- 17.7

- 18

- 18.2

- 18.5

- 18.6

- 19

- 19.05

- 19.5

- 20

- 20.5

- 21

- 21.5

- 21.77

- 22

- 22.3

- 22.5

- 23

- 23.4

- 24

- 25

- 25.0(+0.3)

- 25.20

- 25.3

- 26

- 26.6

- 27

- 28

- 29

- 29.9

- 30

- 30.20

- 30.5

- 31

- 31.5

- 31.7

- 31.9

- 32

- 32.6

- 32.7

- 33.1

- 33.3

- 34

- 34.1

- 34.8

- 34.9

- 35

- 35.4

- 35.9

- 36

- 36.9

- 37

- 37.1

- 37.9

- 38

- 39

- 39.83

- 40

- 43

- 45

- 45.6

- 46

- 48

- 49.85~134.6

- 50

- 50.7

- 52.8

- 53.6

- 53.91

- 54.3

- 55

- 56

- 56.8

- 57.0

- 57.9

- 58.2

- 60

- 61.4

- 62.2

- 63

- 64.6

- 65

- 66

- 67.4

- 67.94

- 69.2

- 69.8

- 70

- 71.8

- 73.3

- 75

- 80

- 90

- 95

- 100

-

Tip angle (θ)

-

Application

-

work material

-

Single blade, two blades

-

Peripheral Blade Y/N

-

Coating Y/N

-

Coating Type

-

R Size (R)(mm)

- 0.1

- 0.15

- 0.2

- 0.25

- 0.3

- 0.35

- 0.4

- 0.45

- 0.5

- R0.5

- 0.5/1/1.5/2

- 0.5 to 4

- 0.5~5

- 0.55

- 0.6

- 0.65

- 0.7

- 0.75

- R0.75

- 0.8

- 0.85

- 0.9

- 0.95

- 1

- 1RM

- 1RY

- R1

- 1, 1.5

- 1/2/3/4

- 1–3

- 1–5

- 1.05

- 1.1

- 1.15

- 1.2

- 1.25

- R1.25

- 1.3

- 1.35

- 1.4

- 1.45

- 1.5

- R1.5

- 1.55

- 1.6

- 1.65

- 1.7

- 1.75

- 1.8

- 1.85

- 1.9

- 1.95

- 2

- 2RM

- 2RY

- R2

- 2, 3

- 2.05

- 2.1

- 2.15

- 2.2

- 2.25

- 2.3

- 2.35

- 2.4

- 2.45

- 2.5

- R2.5

- 2.6

- 2.7

- 2.75

- 2.8

- 2.9

- 3

- 3RM

- 3RY

- R3

- 3.25

- 3.5

- R3.5

- 3.75

- 4

- 4RM

- 4RY

- R4

- 4.25

- 4.5

- R4.5

- 4.75

- 5

- 5RM

- R5

- 5–10

- 5.25

- 5.5

- 5.75

- 6

- R6

- 6.25

- 6.5

- 6.75

- 7

- R7

- 7.25

- 7.5

- 7.75

- 8

- R8

- 8.5

- 9

- R9

- 9.5

- 10

- R10

- 10.5

- 11

- 11.5

- 12

- R12

- 12.5

- R12.5

- 13

- 13.5

- 14

- 14.5

- 15

- R15

- 15.5

- 16

- R16

- 16.5

- 17

- 17.5

- 18

- 18.5

- 19

- 19.5

- 20

- 20.5

- 21

- 21.5

- 22

- 22.5

- 23

- 23.5

- 24

- 24.5

- 25

- 25.5

- 26

- 26.5

- 27

- 27.5

- 28

- 28.5

- 29

- 29.5

- 30

- XRM

- XRY

Related Categories to Chamfering / Centering Tools

-

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy