(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

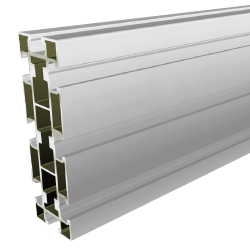

Aluminum Frames(Number of Extrusion Slots:1 Row Groove × 3 Row Groove)

Aluminum frames (a.k.a. aluminum profiles) do not require welding unlike steel frames, are easy to assemble and make design changes, and do not easily develop surface rust.

At MISUMI, we offer a wide lineup of aluminum frames that are available with short delivery, low price and high quality.

[MISUMI's aluminum frames]

* Additional processing is a simple frame processing that does not require drawing instructions, which includes various drilling, 45° cutting and end face tapping.

[SUS Aluminum Frames]

In addition to the basic SF Series, many products in the SF2 Series are available, more lightweight and with higher cost performance while maintaining the original rigidity by reconsidering the cross sectional shape.

Boasts extensive lineups that provide proper materials and usage as well as beautiful appearance, and supports site construction and improvement.

Search by specifying the lower class category

5 Series - Aluminum Frames 20, 25, 40 Square

5 Series - Aluminum Frames 20, 25, 40 Square 6 Series - Aluminum Frames 30, 50, 60, 100 Square

6 Series - Aluminum Frames 30, 50, 60, 100 Square Aluminum Frames 4545,4590

Aluminum Frames 4545,4590

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

4 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Medium/Heavy Structure Frame 48M Frame

YUKIGIKEN

[Features]

· Strong type with 40 x 80 mm cross section.

[Cautions]

· Select hole drilling after confirming the hole positions and directions, etc., in the catalog.

· Minimum length is 40 mm when one-sided hole drilling is selected.

· Minimum length is 55 mm when two-sided hole drilling is selected.Standard Extrusion Size(mm) Extrusion Type_ Number of Slotted Surfaces Surface Treatment Extrusion Size Extrusion Series Extrusion Type Number of Extrusion Slots Surface Milled 40 - Four-Side Slots Black Anodize ~ Clear Anodize 40x80 LECOFRAME 40 Series (For Medium/Heavy Structures) Rectangle Shape 1 Row Groove × 3 Row Groove Not Provided Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Lightweight - Hollow, Frame for Hollow Structure, 255 Frame

YUKIGIKEN

[Features]

· Suitable for light to medium structural beams.

[Cautions]

· Select hole drilling after confirming the hole positions and directions, etc., in the catalog.

· Minimum length is 25 mm when one-sided hole drilling is selected.

· Minimum length is 35 mm when two-sided hole drilling is selected.Standard Extrusion Size(mm) Extrusion Type_ Number of Slotted Surfaces Surface Treatment Extrusion Size Extrusion Series Extrusion Type Number of Extrusion Slots Surface Milled 25 - Four-Side Slots Clear Anodize 25x55 LECOFRAME 25 Series (For Light/Medium Structures) Rectangle Shape 1 Row Groove × 3 Row Groove Not Provided Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Basic Frame M8 Series Heavyweight Class AFS-40120

NIC AUTOTEC

This basic frame is the frame that alpha frame is based on. The outer dimensions and T grooves are designed with standard dimensions, and standard brackets and accessories can be freely combined by bolt coupling.

Standard Extrusion Size(mm) Extrusion Type_ Number of Slotted Surfaces Surface Treatment Extrusion Size Extrusion Series Extrusion Type Number of Extrusion Slots Surface Milled 40 - Four-Side Slots - 40x120 NIC Autotec M8 Series Rectangle Shape 1 Row Groove × 3 Row Groove - Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Medium/Heavy Structural Frame, 412 Frame

YUKIGIKEN

[Features]

· Suitable for beams of heavy structures.

[Cautions]

· Select hole drilling after confirming the hole positions and directions, etc., in the catalog.

· Minimum length is 40 mm when one-sided hole drilling is selected.

· Minimum length is 55 mm when two-sided hole drilling is selected.Standard Extrusion Size(mm) Extrusion Type_ Number of Slotted Surfaces Surface Treatment Extrusion Size Extrusion Series Extrusion Type Number of Extrusion Slots Surface Milled 40 - Four-Side Slots Clear Anodize 40x20 LECOFRAME 40 Series (For Medium/Heavy Structures) Rectangle Shape 1 Row Groove × 3 Row Groove Not Provided Days to Ship: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Standard Extrusion Size(mm) |

| Extrusion Type_ |

| Number of Slotted Surfaces |

| Surface Treatment |

| Extrusion Size |

| Extrusion Series |

| Extrusion Type |

| Number of Extrusion Slots |

| Surface Milled |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | YUKIGIKEN | YUKIGIKEN | NIC AUTOTEC | YUKIGIKEN |

| Product Series | ||||

| CAD |

|

|

|

|

| From | ||||

| Days to Ship | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 9 Day(s) or more |

| Standard Extrusion Size(mm) | 40 | 25 | 40 | 40 |

| Extrusion Type_ | - | - | - | - |

| Number of Slotted Surfaces | Four-Side Slots | Four-Side Slots | Four-Side Slots | Four-Side Slots |

| Surface Treatment | Black Anodize ~ Clear Anodize | Clear Anodize | - | Clear Anodize |

| Extrusion Size | 40x80 | 25x55 | 40x120 | 40x20 |

| Extrusion Series | LECOFRAME 40 Series (For Medium/Heavy Structures) | LECOFRAME 25 Series (For Light/Medium Structures) | NIC Autotec M8 Series | LECOFRAME 40 Series (For Medium/Heavy Structures) |

| Extrusion Type | Rectangle Shape | Rectangle Shape | Rectangle Shape | Rectangle Shape |

| Number of Extrusion Slots | 1 Row Groove × 3 Row Groove | 1 Row Groove × 3 Row Groove | 1 Row Groove × 3 Row Groove | 1 Row Groove × 3 Row Groove |

| Surface Milled | Not Provided | Not Provided | - | Not Provided |

Loading...

Configure

Specification/Dimensions

-

Standard Extrusion Size(mm)

-

Extrusion Type_

-

Number of Slotted Surfaces

-

Four-Side Slots

Four-Side Slots -

Three-Side Slots

Three-Side Slots -

Two-Side Slots

Two-Side Slots -

Two-Side Slots (Opposed)

Two-Side Slots (Opposed) -

One-Side Slots

One-Side Slots

-

-

Surface Treatment

-

Extrusion Size

- 15x15

- 15x25

- 15x30

- 15x40

- 15x120

- 15x150

- 20x20

- 20x25

- 20x30

- 20x40

- 20x60

- 20x80

- 25x25

- 25x32.3

- 25x35.3

- 25x40

- 25x50

- 25x55

- 25x165

- 30x30

- 30x40

- 30x60

- 30x90

- 30x120

- 30x300

- 40x20

- 40x30

- 40x40

- 40x52

- 40x54.7

- 40x60

- 40x80

- 40x120

- 40x160

- 45x45

- 45x90

- 45x180

- 50x25

- 50x50

- 50x100

- 50x200

- 60x20

- 60x30

- 60x40

- 60x60

- 60x90

- 60x120

- 60x180

- 80x20

- 80x40

- 80x80

- 80x160

- 90x30

- 90x45

- 90x60

- 90x90

- 90x180

- 100x50

- 100x100

- 100x150

- 100x200

- 120x120

- 300x30

-

Extrusion Series

- 3 Series

- NIC Autotec M4 Series

- 5 Series

- 6 Series

- NIC Autotec M6 Series

- 8 Series

- NIC Autotec M8 Series

- 8-45 Series

- NIC Autotec H10 Series

- MISUMI, European Standard, Aluminum Frame, LCF 20 Series, (Groove Width: 6 mm)

- LECOFRAME 25 Series (For Light/Medium Structures)

- MISUMI, European Standard, Aluminum Frame, 30/40/50/60 Series, (Groove Width: 8 mm)

- LECOFRAME 40 Series (For Medium/Heavy Structures)

- MISUMI, European Standard, Aluminum Frame, 45/50/60 Series, (Groove Width: 10 mm)

-

Extrusion Type

-

Square Shape

Square Shape -

Rectangle Shape

Rectangle Shape -

R Shape

R Shape -

L Shape

L Shape -

L/R Shape

L/R Shape -

Triangle Shape

Triangle Shape -

Angled Shape

Angled Shape -

Mixed Slot Widths Shape

Mixed Slot Widths Shape -

Bent Shape

Bent Shape -

With C plane

With C plane

-

-

Number of Extrusion Slots

- 1 Row Groove × 0 Row Groove

- 1-row groove × 1-row groove

- 1 Row Groove × 1 Row Groove

- 1 Slot x 1 Slot

- 1 Row Groove × 2 Row Groove

- 1 Slot x 2 Slots

- 1 Row Groove × 3 Row Groove

- 1 Slot x 3 Slots

- 1 Row Groove × 4 Row Groove

- 1 Slot x 4 Slots

- 1 Row Groove × 5 Row Groove

- 1 Slot x 10 Slots

- 2 Row Groove × 0 Row Groove

- 2 Row Groove × 1 Row Groove

- 2 Slots x 1 Slot

- 2 Row Groove × 2 Row Groove

- 2 Slots x 2 Slots

- 2 Row Groove × 3 Row Groove

- 2 Slots x 3 Slots

- 2 Row Groove × 4 Row Groove

- 2 Slots x 4 Slots

- 2 Row Groove × 6 Row Groove

- 3 Slots x 1 Slot

- 3 Row Groove × 2 Row Groove

- 3 Slots x 2 Slots

- 4 Slots x 1 Slot

- 4 Slots x 2 Slots

- 4 Row Groove × 4 Row Groove

- 4 Slots x 4 Slots

- 10 Slots x 1 Slot

-

Surface Milled

- Provided

- Not Provided

Related Categories to Aluminum Frames

-

- Aluminum Frames

- Special AEX

- AEX Units

- Brackets and Joint Parts

- Nuts

- Bolts

- Frame Caps

- Slot Covers

- Handles

- Hinges

- Catches and Locks

- Casters

- Foot Bases for Aluminum Extrusions

- Adjuster Pads

- Panel Mounts

- Curtains, Sheets

- Door Sliders

- Conveyor Parts

- Clamps, Holders, Hooks

- LED Lights

- Jigs, Maintenace Parts

- Concealed(invisible) joint parts/frame with joints

- Accessories for aluminum alloy profiles

- Transparent Plastic Covers

- Perforated Metals, Fences, Nets, Panels

FAQ Aluminium Frames

- Question: What advantages does using aluminum profiles offer?

- Answer: 1. Lightweight: Aluminum profiles are lightweight and making them easy to transport.

2. Strong and durable: Aluminum profiles can withstand weather conditions and resist corrosion.

3. Easy to fabricate and assemble: Reduce complex methods for assembling and dismantling.

4. Non-magnetic: Aluminum profiles are useful in high-voltage applications and in electronics.

5. Variety of standard sizes and shapes: Reduce machining process - Question: What factors should I consider when selecting aluminum profiles?

- Answer: When building a machine structure, it's important to consider for example

1. Application and environment: Consider both the purpose and the environment it will be used in. For example, a structure the machine for electronic industries,

2. Profile shape and dimensions: Aluminum profiles come in many shapes and sizes, each with a various number of slots that can impact the ease of assembly and strength of the structure

3. Material: The material used for the profiles is also important such as 6061 and 6063 is suitable for structure of machine

4. Surface treatment: It is not just for aesthetics; it can also enhance corrosion resistance and provide advantages for mounting additional equipment. Rough surfaces are better for applications where grip or adhesion is required.

5. Price: It is an additional factor to consider, but it's important to remember that a cheaper manufacturer may not be as effective in the long term. otherwise, a higher-priced option can ultimately result in lower maintenance costs and a more durable structure. - Question: Can aluminum profiles get rust?

- Answer: No, the rusting reaction cannot occur in aluminum profiles because they do not contain iron, which is one of the three factors required for the oxidation reaction that causes the formation of iron rust. The rusting reaction involves the presence of water, moisture, and iron element, which react to form an oxide compound or rust. Since aluminum is a non-metallic element, it does not participate in this reaction, leading to an incomplete rusting process.

- Question: What advantages does aluminum have over steel?

- Answer: 1. Weight: Aluminum is much lighter than steel. Its density is about one-third that of steel. This makes aluminum a popular choice for applications where weight is a critical factor, such as in the aerospace industry. the automotive industry, etc.

2. Corrosion resistance: Aluminum is inherently resistant to corrosion. Since it is a non-metal element, it does not contain metal, so it does not rust. making it a popular choice for outdoor use

3. Thermal Conductivity: Aluminum has excellent thermal conductivity, which makes it a popular choice. For designing equipment parts such as heat exchangers. in air conditioners, etc.

4. Appearance : : Aluminum has a clean, modern look and is available in a wide range of colors and finishes. No additional painting is required like steel. - Question: Which blade is recommended for cutting aluminum profiles effectively?

- Answer: When cutting aluminum profiles, it is important to use a blade that is specifically designed for cutting non-ferrous metals, so the most effective blade for cutting aluminum profiles is a carbide-tipped saw blade with a high tooth count. A blade with at least 80 teeth is recommended, as this will help prevent the aluminum from "gumming up" the blade and causing it to bind or overheat during cutting

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy