(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 24/11/2024 to 4:30 (IST) 25/11/2024. We apologize for the inconvenience.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Ball Bearings(Outer Ring Type:Flat Page3)

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

| Days to Ship |

|

92 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

SH Series Stainless Steel Bearing SSA Type With Aligning Features

NANKAISEIKOJO

Stainless steel bearing made of SUS440C which is designed to tolerate deflection of a large roller and features an extended maintenance period due to implementation of an aligning function.

[Features]

· The inclusion of an alignment function to a conventional stainless bearing makes it possible to support deflection of large rollers such as chemical film rollers, and by adding the corrosion resistance of stainless steel the maintenance period has been greatly increased.

· Because SUS440C stainless steel is used, the bearing is ideal for corrosive environments, clean rooms and food processing equipment.

· By adjusting the axial center error caused by deflection of the shaft of transport rollers, etc. as well as mounting failure, abnormal loads on the bearing are reduced.

· Both the seal and shield serve as a sealing device, to prevent infiltration of dirt, dust, solutions, etc.Inner Dia. d(Ø) Outer Dia. D(Ø) Width B(mm) Raceway Ring Shape Bearing Type Outer Ring Type Inner/Outer Ring Material Basic Dynamic Load Rating(N) Specifications, Environment Precision (JIS) Load Direction Rolling Element Material Size Standards Number of Raceway Ring Rows 10 ~ 30 30 ~ 72 9 ~ 19 Self-Aligning Ball Open Flat Stainless Steel 4600 ~ 19500 Heat Resistant / Non-magnetic / Rust-Prevention / Dust Resistant / For High Speed / Corrosion Resistant Class 0 Radial / Thrust Stainless Steel Metric System Single Row From: ₹ 5,453.02 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

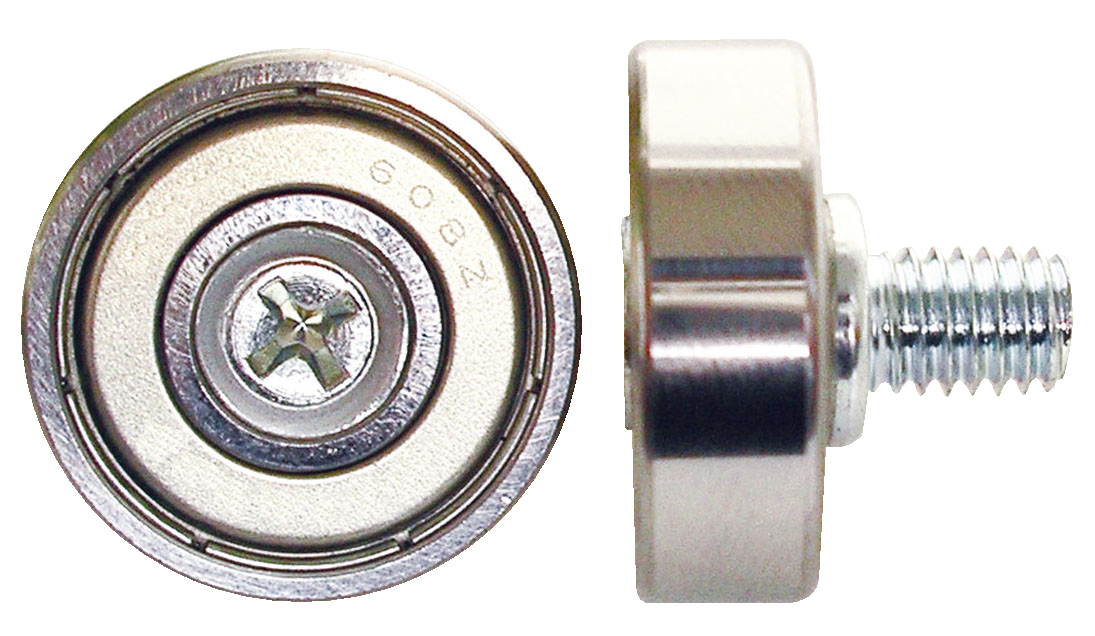

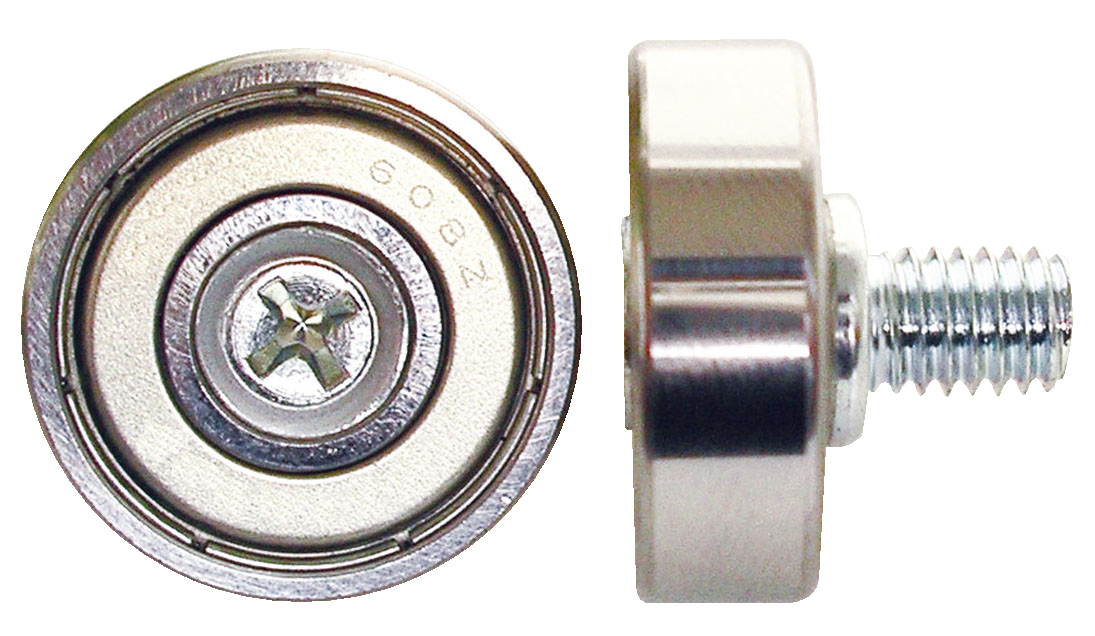

Bearing with Bolt Steel-Made Cross Groove Type

EASTERN SEIKO

Bolts are swaged to precision bearings ensuring no looseness.

Inner Dia. d(Ø) Outer Dia. D(Ø) Width B(mm) Raceway Ring Shape Bearing Type Outer Ring Type Inner/Outer Ring Material Basic Dynamic Load Rating(N) Specifications, Environment Precision (JIS) Load Direction Rolling Element Material Size Standards Number of Raceway Ring Rows M6 15 ~ 22 5 ~ 7 Ball Double Shielded Flat Steel 80 Standard - Radial Steel Metric System Single Row From: ₹ 390.69 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Inner Dia. d(Ø) |

| Outer Dia. D(Ø) |

| Width B(mm) |

| Raceway Ring Shape |

| Bearing Type |

| Outer Ring Type |

| Inner/Outer Ring Material |

| Basic Dynamic Load Rating(N) |

| Specifications, Environment |

| Precision (JIS) |

| Load Direction |

| Rolling Element Material |

| Size Standards |

| Number of Raceway Ring Rows |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | NANKAISEIKOJO | EASTERN SEIKO |

| Product Series | SH Series Stainless Steel Bearing SSA Type With Aligning Features | |

| CAD |

| |

| From | ₹ 5,453.02 | ₹ 390.69 |

| Days to Ship | 5 Day(s) or more | 5 Day(s) or more |

| Inner Dia. d(Ø) | 10 ~ 30 | M6 |

| Outer Dia. D(Ø) | 30 ~ 72 | 15 ~ 22 |

| Width B(mm) | 9 ~ 19 | 5 ~ 7 |

| Raceway Ring Shape | Self-Aligning Ball | Ball |

| Bearing Type | Open | Double Shielded |

| Outer Ring Type | Flat | Flat |

| Inner/Outer Ring Material | Stainless Steel | Steel |

| Basic Dynamic Load Rating(N) | 4600 ~ 19500 | 80 |

| Specifications, Environment | Heat Resistant / Non-magnetic / Rust-Prevention / Dust Resistant / For High Speed / Corrosion Resistant | Standard |

| Precision (JIS) | Class 0 | - |

| Load Direction | Radial / Thrust | Radial |

| Rolling Element Material | Stainless Steel | Steel |

| Size Standards | Metric System | Metric System |

| Number of Raceway Ring Rows | Single Row | Single Row |

Loading...

Configure

Specification/Dimensions

-

Inner Dia. d(Ø)

- 1

- 1.5

- 2

- 2.5

- 3

- 3.175/0.1250

- 4

- M4

- 4.762/0.1875

- 5

- 6

- M6

- 6.350/0.2500

- 7

- 8

- M8

- 9

- 9.525/0.3750

- 10

- 12

- 12.700/0.5000

- 13

- 14

- 15

- 15.875/0.6250

- 16

- 17

- 18

- 19

- 20

- 22

- 25

- 27

- 28

- 30

- 32

- 35

- 37

- 40

- 42

- 45

- 47

- 50

- 52

- 55

- 57

- 57.150

- 60

- 62

- 65

- 67

- 68

- 70

- 72

- 75

- 77

- 80

- 85

- 90

- 93

- 95

- 100

- 103

- 105

- 110

- 113

- 120

- 123

- 130

- 133

- 140

- 143

- 144

- 150

- 160

- 163

- 170

- 180

- 190

- 200

- 204

- 220

- 240

- 260

- 280

- 300

- 304

- 320

- 340

- 360

- 380

- 400

- 420

- 440

- 460

-

Outer Dia. D(Ø)

- 3

- 4

- 5

- 6

- 7

- 8

- 8.1

- 8.2

- 9

- 9.5

- 9.525/0.3750

- 10

- 10.2

- 11

- 11.5

- 11.6

- 12

- 12.2

- 12.5

- 12.700/0.5000

- 13

- 13.5

- 14

- 14.6

- 15

- 15.6

- 15.875/0.6250

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 22.225/0.8750

- 23

- 24

- 25

- 26

- 27

- 28

- 28.575/1.1250

- 30

- 31

- 32

- 34.925/1.3750

- 35

- 37

- 38

- 40

- 42

- 44

- 47

- 50

- 52

- 55

- 56

- 58

- 60

- 62

- 65

- 68

- 70

- 72

- 73

- 74

- 75

- 78

- 80

- 82

- 85

- 90

- 95

- 100

- 105

- 110

- 115

- 120

- 125

- 130

- 135

- 140

- 145

- 149.225

- 150

- 155

- 160

- 165

- 170

- 175

- 180

- 190

- 195

- 200

- 210

- 215

- 220

- 225

- 230

- 235

- 240

- 250

- 260

- 270

- 280

- 290

- 300

- 310

- 320

- 340

- 350

- 360

- 380

- 400

- 420

- 430

- 440

- 460

- 480

- 500

- 520

- 540

- 560

- 580

- 600

- 620

-

Width B(mm)

- 1

- 1.2

- 1.5

- 1.6

- 1.8

- 2

- 2.3

- 2.5

- 2.6

- 2.8

- 3

- 3.5

- 3.967/0.1562

- 4

- 4.5

- 4.978/0.1960

- 5

- 5.5

- 6

- 6.5

- 7

- 7.142/0.2812

- 7.72

- 7.938/0.25

- 7.938/0.3125

- 8

- 8.6

- 8.733/0.3438

- 9

- 9.6

- 10

- 10.4

- 10.5

- 11

- 12

- 12.36

- 13

- 13.64

- 14

- 14.3

- 15

- 15.5

- 15.9

- 16

- 17

- 17.5

- 18

- 19

- 20

- 20.6

- 21

- 22

- 22.2

- 23

- 23.8

- 24

- 25

- 25.4

- 26

- 27

- 28

- 29

- 30

- 30.2

- 31

- 32

- 33

- 33.3

- 34

- 34.9

- 35

- 36

- 36.5

- 37

- 38

- 38.1

- 39

- 39.7

- 40

- 41

- 41.3

- 42

- 43

- 44

- 44.4

- 45

- 46

- 47

- 48

- 49

- 49.2

- 50

- 51

- 52

- 53

- 54

- 54.229

- 55

- 56

- 57

- 58

- 58.7

- 59

- 60

- 61

- 62

- 63

- 63.5

- 64

- 65

- 66

- 67

- 68

- 70

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 86

- 87

- 88

- 89

- 90

- 92

- 94

- 95

- 105

- 110

- 112

- 117

- 128

- 130

-

Raceway Ring Shape

-

Ball

Ball -

Self-Aligning Ball

Self-Aligning Ball -

Angular Bearing (Single)

Angular Bearing (Single) -

Angular Bearing (Double)

Angular Bearing (Double) -

Thrust Bearing

Thrust Bearing

-

-

Bearing Type

-

Open

Open -

Double Shielded

Double Shielded -

Rubber Sealed

Rubber Sealed -

Single Shielded

Single Shielded

-

-

Outer Ring Type

- Flat

- Spherical

- With V-Shaped Groove

- With U-Shaped Groove

- With Retaining Ring Grooves

- With Flange

- Deep Groove

-

Inner/Outer Ring Material

- Steel

- Stainless Steel

- Plastic

-

Basic Dynamic Load Rating(N)

- 0.6

- 0.64

- 0.66

- 0.7

- 0.73

- 1,610

- 1.28

- 1.34

- 1.46

- 1.89

- 2.02

- 2.56$350000

- 2.8

- 3,350

- 3.01

- 3.19

- 3.26

- 3.57

- 3.92

- 4,300

- 4.27

- 4.48

- 4.76

- 4.94

- 5,100

- 5.43

- 5.74

- 6.58

- 6.72

- 6.79

- 7,600

- 7,750

- 7.07

- 7.98

- 8,300

- 8.96

- 9,400

- 9,600

- 9,700

- 9.24

- 9.45

- 9.8

- 11.13

- 12,800

- 13.65

- 14,000

- 14.84

- 15,900

- 26,700

- 28,500

- 36,000

- 36,500

- 40,000

- 41,500

- 44,500

- 52

- 66

- 67

- 76,500

- 80

- 85

- 91

- 95

- 100

- 100.1

- 102

- 104

- 105

- 106

- 111

- 112

- 120

- 122

- 123.9

- 124

- 124.6

- 125

- 129

- 129.5

- 136

- 138

- 143

- 144

- 146

- 151.9

- 152

- 153

- 155

- 159

- 167

- 169

- 171

- 174

- 177

- 178

- 185

- 187

- 188

- 192

- 195

- 196

- 196.7

- 197

- 199

- 200

- 208

- 209

- 212

- 217

- 218

- 221

- 222

- 229

- 229.6

- 231

- 231.7

- 235

- 236

- 237

- 242

- 251

- 255

- 256

- 258

- 270

- 273

- 275

- 277

- 278

- 281

- 282

- 288

- 289

- 292

- 294

- 294.7

- 304

- 308

- 310

- 311

- 319

- 323.4

- 324

- 325

- 326

- 327

- 328

- 330

- 331

- 331.8

- 332

- 339

- 339.5

- 340

- 347

- 350

- 355

- 360

- 361

- 365

- 366

- 375

- 375.2$296000

- 380

- 380.8

- 381

- 381.5

- 385

- 386

- 387

- 390

- 392

- 395

- 396

- 399

- 400

- 407

- 408

- 421

- 424

- 424.9

- 430

- 431

- 434

- 438

- 441

- 442

- 448

- 455

- 459

- 462

- 463

- 465

- 468

- 470

- 473

- 474

- 476

- 478.8

- 480

- 484

- 485

- 490

- 495

- 496

- 497

- 500

- 500.5

- 501

- 505

- 510

- 515

- 520

- 535

- 536

- 540

- 541

- 542

- 543

- 544

- 545

- 547

- 550.9

- 552

- 555

- 557.2

- 558

- 560

- 569

- 570

- 571

- 598.5

- 599

- 600

- 604

- 607

- 608

- 630

- 631

- 635

- 640

- 640.5

- 641

- 642.6

- 643

- 648

- 648.2

- 650

- 657

- 658

- 660

- 663

- 669.9

- 670

- 677

- 680

- 684

- 686

- 694

- 697

- 700

- 710

- 711

- 714

- 715

- 716

- 730

- 740

- 755

- 756

- 756$17900

- 773

- 773.5

- 780

- 784

- 787

- 795

- 796

- 797

- 797.3

- 799

- 800

- 813

- 814

- 815

- 816

- 817

- 820

- 825

- 830

- 850

- 855

- 859

- 867

- 868

- 874

- 875

- 910

- 912

- 915

- 918

- 919

- 920

- 926

- 930

- 931

- 937

- 938

- 940

- 945

- 945$4930

- 950

- 957

- 957.6

- 958

- 960

- 969

- 970

- 995

- 1000

- 1021.3

- 1025

- 1028.3

- 1029

- 1040

- 1041

- 1046

- 1048

- 1077

- 1080

- 1082

- 1091

- 1100

- 1105

- 1120

- 1127

- 1130

- 1131

- 1139

- 1140

- 1142

- 1143

- 1170

- 1173

- 1182

- 1201

- 1210

- 1210.3

- 1211

- 1233.4

- 1250

- 1252

- 1280

- 1283

- 1300

- 1301

- 1310

- 1327

- 1329

- 1330

- 1330.7

- 1331

- 1340

- 1340.5

- 1341

- 1344

- 1344.7

- 1350

- 1360

- 1368

- 1369

- 1389.5

- 1390

- 1393

- 1400

- 1402

- 1451

- 1451.1

- 1459

- 1460

- 1462

- 1469

- 1470

- 1471

- 1480

- 1509.2

- 1533

- 1560

- 1563

- 1563.1

- 1579

- 1605

- 1610

- 1630

- 1635

- 1635.2

- 1638

- 1650

- 1665

- 1686

- 1716

- 1717.1

- 1720

- 1729

- 1730

- 1760

- 1762

- 1770

- 1777

- 1790

- 1830

- 1866

- 1883

- 1887

- 1890

- 1900

- 1901

- 1904

- 1915

- 1920

- 1921

- 1924

- 1959

- 1959.3

- 1983

- 1985

- 1986

- 1989

- 1990

- 2020

- 2020.2

- 2030

- 2032

- 2070

- 2073

- 2080

- 2090

- 2120

- 2150

- 2156

- 2176

- 2185

- 2190

- 2230

- 2233

- 2237

- 2240

- 2260

- 2263

- 2290

- 2304

- 2308

- 2321

- 2336

- 2340

- 2345

- 2350

- 2390

- 2450

- 2453

- 2467

- 2480

- 2490

- 2516

- 2530

- 2560

- 2570.4

- 2580

- 2593

- 2630

- 2645

- 2670

- 2687

- 2695

- 2700

- 2715

- 2730

- 2750

- 2760

- 2799

- 2800

- 2810.5

- 2811

- 2831

- 2833

- 2883

- 2886

- 2890

- 2900

- 3000

- 3010

- 3012

- 3012.1

- 3024.7

- 3025

- 3026

- 3190

- 3194

- 3200

- 3211.6

- 3212

- 3222

- 3260

- 3287

- 3290

- 3293

- 3300

- 3313

- 3327

- 3330

- 3332

- 3333

- 3350

- 3356

- 3399

- 3400

- 3410

- 3430

- 3443

- 3450

- 3484

- 3530

- 3560

- 3570

- 3650

- 3660

- 3660$8200

- 3670

- 3672

- 3700

- 3790

- 3857

- 3860

- 3868

- 3870

- 3879

- 3900

- 3910

- 3920

- 4000

- 4015

- 4020

- 4089

- 4150

- 4180

- 4185

- 4270

- 4300

- 4303

- 4321

- 4325

- 4330

- 4340

- 4350

- 4400

- 4450

- 4466.7

- 4467

- 4480

- 4500

- 4538

- 4540

- 4550

- 4560

- 4563

- 4575

- 4588

- 4590

- 4600

- 4620

- 4650

- 4658

- 4659

- 4700

- 4707

- 4729

- 4740

- 4750

- 4752

- 4760

- 4810

- 4837

- 4900

- 4900.7

- 4901

- 4905

- 4923

- 4930

- 4940

- 4950

- 5000

- 5050

- 5080

- 5090

- 5100

- 5108

- 5109

- 5200

- 5259

- 5300

- 5350

- 5400

- 5420

- 5430

- 5450

- 5500

- 5550

- 5590

- 5600

- 5610

- 5619

- 5690

- 5700

- 5740

- 5770

- 5780

- 5800

- 5900

- 5950

- 5992

- 5999

- 6000

- 6010

- 6100

- 6119

- 6150

- 6187

- 6210

- 6250

- 6350

- 6374

- 6381

- 6400

- 6477

- 6490

- 6500

- 6580

- 6600

- 6610

- 6690

- 6720

- 6750

- 6786

- 6790

- 6800

- 6843

- 6870

- 6900

- 6950

- 7000

- 7001

- 7002

- 7050

- 7070

- 7100

- 7150

- 7237

- 7242

- 7250

- 7280

- 7300

- 7350

- 7400

- 7420

- 7450

- 7500

- 7550

- 7600

- 7620

- 7650

- 7700

- 7750

- 7800

- 7850

- 7900

- 7950

- 7960

- 7980

- 7990

- 8000

- 8024

- 8050

- 8090

- 8100

- 8130

- 8150

- 8200

- 8240

- 8250

- 8330

- 8350

- 8500

- 8540

- 8550

- 8590

- 8600

- 8630

- 8650

- 8750

- 8800

- 8850

- 8950

- 8960

- 9000

- 9050

- 9240

- 9265

- 9270

- 9300

- 9310

- 9385

- 9400

- 9440

- 9450

- 9500

- 9550

- 9600

- 9650

- 9699

- 9700

- 9710

- 9750

- 9800

- 9870

- 9877

- 9900

- 9950

- 10000

- 10062

- 10100

- 10150

- 10200

- 10300

- 10400

- 10404

- 10500

- 10570

- 10600

- 10699

- 10700

- 10800

- 10880

- 10900

- 10910

- 11000

- 11100

- 11130

- 11200

- 11220

- 11240

- 11300

- 11400

- 11434

- 11500

- 11550

- 11600

- 11626

- 11630

- 11690

- 11700

- 11760

- 11800

- 11900

- 11980

- 11985

- 12000

- 12100

- 12110

- 12200

- 12240

- 12300

- 12350

- 12359

- 12400

- 12500

- 12600

- 12700

- 12800

- 12900

- 13000

- 13100

- 13200

- 13229

- 13300

- 13400

- 13490

- 13500

- 13560

- 13600

- 13621

- 13650

- 13678

- 13700

- 13790

- 13900

- 14000

- 14014

- 14100

- 14200

- 14250

- 14280

- 14300

- 14400

- 14420

- 14500

- 14540

- 14600

- 14630

- 14700

- 14800

- 14840

- 14900

- 15000

- 15100

- 15150

- 15200

- 15260

- 15300

- 15400

- 15600

- 15750

- 15800

- 15900

- 15936

- 15965

- 16000

- 16100

- 16200

- 16400

- 16500

- 16530

- 16600

- 16700

- 16769

- 16800

- 16900

- 17000

- 17200

- 17300

- 17400

- 17490

- 17500

- 17600

- 17765

- 17800

- 17990

- 18000

- 18100

- 18200

- 18300

- 18400

- 18500

- 18510

- 18530

- 18600

- 18690

- 18700

- 18800

- 18900

- 19000

- 19100

- 19200

- 19300

- 19400

- 19456

- 19500

- 19600

- 19700

- 19800

- 20000

- 20200

- 20300

- 20370

- 20400

- 20500

- 20584

- 20600

- 20650

- 20700

- 20800

- 20900

- 21000

- 21200

- 21300

- 21400

- 21600

- 21700

- 21800

- 21810

- 21845

- 21900

- 22000

- 22050

- 22100

- 22200

- 22300

- 22400

- 22500

- 22630

- 22695

- 22700

- 22800

- 23000

- 23100

- 23300

- 23450

- 23500

- 23600

- 23700

- 23800

- 24000

- 24400

- 24500

- 24600

- 24730

- 24735

- 24800

- 24900

- 25000

- 25100

- 25200

- 25300

- 25400

- 25683

- 25700

- 25900

- 26000

- 26200

- 26300

- 26400

- 26500

- 26700

- 26775

- 26800

- 26900

- 27000

- 27100

- 27300

- 27500

- 27600

- 27790

- 27800

- 27900

- 28000

- 28100

- 28200

- 28300

- 28350

- 28400

- 28475

- 28500

- 28600

- 28800

- 28900

- 29000

- 29100

- 29300

- 29400

- 29500

- 29600

- 29700

- 29750

- 29800

- 29900

- 30200

- 30400

- 30500

- 31000

- 31100

- 31400

- 31500

- 31900

- 32000

- 32500

- 32700

- 33000

- 33300

- 33500

- 33600

- 33700

- 34000

- 34100

- 34425

- 34500

- 34700

- 35000

- 35100

- 35500

- 36000

- 36200

- 36500

- 37000

- 37100

- 37500

- 37700

- 38000

- 38100

- 38400

- 38500

- 39000

- 39400

- 39500

- 40000

- 40500

- 40700

- 41000

- 41500

- 42000

- 42500

- 42700

- 43000

- 43400

- 43500

- 43600

- 44000

- 44500

- 44900

- 45000

- 45050

- 45400

- 45500

- 45700

- 46000

- 46500

- 47000

- 47500

- 48000

- 48500

- 48700

- 49000

- 49500

- 50000

- 50500

- 51000

- 51300

- 51500

- 51800

- 52000

- 52400

- 52500

- 52700

- 53000

- 53400

- 53500

- 54000

- 54400

- 54500

- 54600

- 54700

- 55000

- 55500

- 56000

- 56500

- 57000

- 57200

- 57500

- 58000

- 58500

- 58900

- 59000

- 59500

- 60000

- 60500

- 61300

- 61500

- 62000

- 62500

- 63000

- 63500

- 64000

- 64500

- 64600

- 65000

- 65200

- 66000

- 66500

- 66600

- 67000

- 67300

- 67500

- 68000

- 68400

- 68500

- 69000

- 69300

- 69500

- 69800

- 70000

- 70500

- 70900

- 71000

- 71500

- 72000

- 72500

- 73000

- 73500

- 74000

- 74500

- 75000

- 75300

- 75500

- 76000

- 76500

- 77000

- 77500

- 78000

- 78500

- 79000

- 79100

- 79200

- 79500

- 80000

- 80500

- 81500

- 82000

- 83000

- 83500

- 84000

- 84500

- 85000

- 85300

- 86000

- 86500

- 86700

- 87000

- 87200

- 87500

- 88000

- 88500

- 88600

- 89000

- 90000

- 92500

- 93000

- 93500

- 94000

- 94500

- 95000

- 95500

- 95700

- 96000

- 96500

- 97000

- 97500

- 98000

- 98500

- 98600

- 99000

- 100000

- 101000

- 102000

- 103000

- 104000

- 105000

- 106000

- 107000

- 108000

- 109000

- 110000

- 111000

- 112000

- 113000

- 114000

- 115000

- 116000

- 117000

- 118000

- 119000

- 120000

- 121000

- 122000

- 123000

- 124000

- 125000

- 126000

- 128000

- 129000

- 130000

- 133000

- 134260

- 135000

- 136000

- 137000

- 139000

- 140000

- 141000

- 142000

- 143000

- 144000

- 145000

- 146000

- 147000

- 148000

- 149000

- 153000

- 154000

- 155000

- 156000

- 157000

- 159000

- 160000

- 161000

- 162000

- 164000

- 165000

- 166000

- 167000

- 168000

- 170000

- 171000

- 172000

- 173000

- 175000

- 176000

- 177000

- 180000

- 181000

- 183000

- 184000

- 185000

- 186000

- 187000

- 188000

- 189000

- 190000

- 191000

- 192000

- 193000

- 196000

- 197000

- 198000

- 201000

- 202000

- 203000

- 205000

- 207000

- 208000

- 212000

- 214000

- 218000

- 219000

- 220000

- 223000

- 224000

- 225000

- 227000

- 228000

- 229000

- 232000

- 233000

- 234000

- 235000

- 236000

- 237000

- 238000

- 239000

- 240000

- 241000

- 244000

- 245000

- 246000

- 248000

- 249000

- 250000

- 252000

- 253000

- 255000

- 258000

- 263000

- 266000

- 269000

- 272000

- 273000

- 274000

- 275000

- 276000

- 277000

- 278000

- 280000

- 282000

- 284000

- 287000

- 289000

- 291000

- 297000

- 300000

- 305000

- 310000

- 315000

- 320000

- 325000

- 330000

- 335000

- 340000

- 345000

- 350000

- 355000

- 365000

- 370000

- 375000

- 380000

- 390000

- 400000

- 405000

- 410000

- 415000

- 430000

- 435000

- 455000

- 460000

- 465000

- 480000

- 510000

- 525000

- 530000

- 540000

- 550000

- 640000

-

Specifications, Environment

- Standard

- Heat Resistant

- Water Resistant

- Abrasion Resistant

- Non-magnetic

- Rust-Prevention

- Dust Resistant

- For Vacuum

- For High Speed

- Corrosion Resistant

-

Precision (JIS)

- Class 0

- Class 2

- Class 4

- Class 5

- Class 6

-

Load Direction

-

Rolling Element Material

-

Size Standards

-

Number of Raceway Ring Rows

Related Categories to Ball Bearings

FAQ Bearing

- Question: How to select the right ball bearing for your application

- Answer: 1. Choose a bearing that is fit to the "Bore" and "Shaft’s diameter" for not being loose in installation and causing misalignment.

2. Choose a bearing that is matched to the shaft's rotating speed to reduce heat in the "Ball" and "Ring" that will make bearings deteriorate.

3. Choose a bearing that is matched to the "radial load" and "axial load" of the application.

4. Choose a bearing that has clearance that matches the temperature in the operation area, like the conveyor of a furnace, because "Ball" and "Ring" will expand from heat and create more.

5. Choose a bearing that is compatible with the environment of the operation area, like a bearing that has a dust cover to prevent dust from creeping in or a bearing that is capable of heat resistance. - Question: What are bearing types and their various applications

- Answer: Normally, bearing can be divided into 2 groups:

1. Rolling-element bearings that contain "Balls" or "Rollers" between the "Outer - Inner Rings" to carry loads These bearings have 2 types.

1.1. Ball bearing: use balls as rolling elements. It can take bolt "Radial Load" and "Axial Load". Example: Bearing in a Bicycle’s Wheel.

1.2. Roller bearing: use rollers as rolling elements. Good to carry "Radial Load". Example: Bearing in the Conveyor’s Pulley.

2. Plain bearing: It has 2 components. 1st is "Journal" which is a hollow cylinder case, and "Journal Bearing" which is an inside bore. This plain bearing uses oil as lubrication and is capable of self-alignment. Good for low rotating speed and eccentric force like an excavator cylinder rod end. - Question: How to read and use a ball bearing size chart? Please use this picture

- Answer:

Basically, bearing size tables contain 4 columns.

- 1st column is Part Number.

- 2nd column is "Inside Diameter" or “d” which tells the size of the shaft.

- 3rd column is "Outside Diameter" or “D” which tells the size of the bore.

- 4th column is “Bore” or “B” which tells the width of the bearing so that it can be installed properly.

- Some types of bearing size chart might have other columns for more detail. Such as rotating speed, basic load rating, mass etc.

The above information is referenced from Product catalog from MISUMI. In some manufacturers, the order of the tables may slightly change. - Question: What are the different types of ball bearings?

- Answer: - There are many types, each suited for specific applications. Here are some common ones:

- Deep groove ball bearings: Handle both radial and light axial loads (most common type).

- Angular contact bearings: Designed for primarily radial loads or a combination of radial and axial loads.

- Thrust bearings: Primarily handle axial loads.

- Self-aligning ball bearings: Can accommodate some misalignment between the shaft and housing.

- Linear ball bearings: Allow for smooth linear motion along a shaft. - Question: What are bearing materials and their properties

- Answer: - Carbon steel is the cheapest and strongest, but the material has low heat resistance and is not able to take high loads or a high rotating speed.

- Chrome steel is stronger and able to take a higher load than carbon steel, but it requires lubrication. and the material is not resistant to chemicals and corrosion.

- Stainless steel has high efficiency, strong, and resistant to corrosion. but it’s heavy, requires lubrication. and expensive.

- Ceramic have high-temperature resistant, resistant to corrosion and light weight. but load capacity is lower than steel Bearing.

- Polymer have many varieties: nylon, polyethylene (PE), etc. The Polymer’s bearing has low-friction properties, light weight, resistance to rust. but it’s expensive and low of heat resistance.

- Hybrid is created by combining materials for the highest load capacity. capable of being heat-resistant and be able to work under conditions of high rotating speed. But it’s extremely expensive and hard to find. So, it has been used for specific applications only. - Question: How to troubleshoot common problems with ball bearings

- Answer: 1. Flaking: Mostly, this problem arises from fractions that creep into bearing. made the ball/Roller or roller scratch with internal parts. This could be prevented by using bearings that have a dust cover and lubricating them with grease.

2. Rusting: The source of this problem comes from water/humidity that gets inside the bearing. Lubrication by using grease is going to coat the bearing’s surface and prevent contact with humidity in the air.

3. Cage distortion: Mostly, this problem comes from drop bearings. But in any case, misassembling is also the cause of the problem. Example Clearance after assembly is not up to standard. Made it to have a gap that balls bump with cage.

4. Fracture: This could be caused by many reasons, but in summary, it is caused by bearings taking a higher load than is allowable. like using the wrong type of bearing or a machine working in the wrong condition. - Question: What distinguishes a simple ball bearing from a deep groove ball bearing?

- Answer: Deep Grove Ball Bearings have a raceway that fits the size of the balls. That’s made the Deep Grove Ball Bearing more stable and able to take a higher load than a normal bearing. Still, it has low-friction properties and can take both radial and axial loads.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy