(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 24/11/2024 to 4:30 (IST) 25/11/2024. We apologize for the inconvenience.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

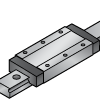

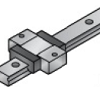

IKO Standard Linear Guides(Material:Carbon Steel)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

IKO

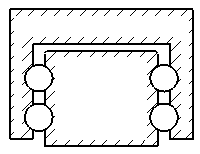

Aiming for compactness on all sides. A universal type linear motion guiding device that has high versatility.

[Features]

· A universal series that is compact and has high versatility

· Wide variation that responds to needs

· A stainless steel line up with excellent corrosion resistance

· A low noise linear way E that achieves smooth and quiet work- CAD :

- 2D

Rail Length L(mm) Block Type Rail Width(mm) Mounting Height H(mm) Nominal Part Number Rail Type Set / Single Item Preload Accuracy Material Ball Arrangement No. of Blocks Retainer Block Mounting Hole Pitch (Width Direction)(mm) Block Mounting Hole Pitch (Length Direction)(mm) Block Mounting Hole Diameter Rail Mounting Hole Pitch(mm) Rail Mounting Hole Diameter 42 ~ 3000 - - - - - - Standard - Carbon Steel - 1 / 2 / 3 / 4 / 5 / 6 / 7 / 8 / 9 - - - - - - Days to Ship: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Rail Length L(mm) |

| Block Type |

| Rail Width(mm) |

| Mounting Height H(mm) |

| Nominal Part Number |

| Rail Type |

| Set / Single Item |

| Preload |

| Accuracy |

| Material |

| Ball Arrangement |

| No. of Blocks |

| Retainer |

| Block Mounting Hole Pitch (Width Direction)(mm) |

| Block Mounting Hole Pitch (Length Direction)(mm) |

| Block Mounting Hole Diameter |

| Rail Mounting Hole Pitch(mm) |

| Rail Mounting Hole Diameter |

You can add up to 6 items per a category to the compare list. | |

| Brand | IKO |

| Product Series | |

| CAD |

|

| From | - |

| Days to Ship | 9 Day(s) or more |

| Rail Length L(mm) | 42 ~ 3000 |

| Block Type | - |

| Rail Width(mm) | - |

| Mounting Height H(mm) | - |

| Nominal Part Number | - |

| Rail Type | - |

| Set / Single Item | - |

| Preload | Standard |

| Accuracy | - |

| Material | Carbon Steel |

| Ball Arrangement | - |

| No. of Blocks | 1 / 2 / 3 / 4 / 5 / 6 / 7 / 8 / 9 |

| Retainer | - |

| Block Mounting Hole Pitch (Width Direction)(mm) | - |

| Block Mounting Hole Pitch (Length Direction)(mm) | - |

| Block Mounting Hole Diameter | - |

| Rail Mounting Hole Pitch(mm) | - |

| Rail Mounting Hole Diameter | - |

Loading...

Configure

Specification/Dimensions

-

Rail Length L(mm)

- 25

- 35

- 39

- 40

- 45

- 50

- 55

- 70

- 75

- 80

- 85

- 95

- 100

- 110

- 115

- 120

- 130

- 135

- 140

- 145

- 150

- 155

- 160

- 170

- 175

- 190

- 195

- 200

- 215

- 220

- 230

- 235

- 245

- 255

- 260

- 270

- 275

- 280

- 290

- 295

- 310

- 315

- 320

- 335

- 340

- 345

- 350

- 355

- 360

- 370

- 390

- 395

- 400

- 420

- 430

- 440

- 445

- 460

- 470

- 495

- 510

- 520

- 545

- 550

- 570

- 580

- 590

- 595

- 600

- 620

- 630

- 640

- 645

- 670

- 680

- 695

- 700

- 720

- 760

- 820

- 840

- 880

- 920

- 940

- 1000

- 1060

- 1080

- 1120

- 1160

- 1180

- 1240

- 1300

- 1320

- 1360

- 1400

- 1420

- 1480

- 1540

- 1560

- 1600

- 1640

- 1660

- 1720

- 1780

- 1800

- 1840

- 1880

- 1900

- 1960

[42-3000/1mm Unit(s)]

-

Block Type

-

Standard

Standard -

Short

Short -

Wide

Wide -

Wide Long

Wide Long -

Long

Long -

Extra Long

Extra Long -

Wide Short

Wide Short

-

-

Rail Width(mm)

-

Mounting Height H(mm)

-

Nominal Part Number

-

Rail Type

-

Standard

Standard -

Wide

Wide

-

-

Set / Single Item

- Set

- Block Only

- Rail Only

-

Preload

- Standard

- Light Preload

- Medium Preload

- Clearance

- Heavy Preload

See the accuracy standard of each manufacturer.

-

Accuracy

- Standard Grade

- High Grade

- Precision Grade

- High Precision Grade

- Ultra Precision Grade

See the accuracy standard of each manufacturer.

-

Material

-

Ball Arrangement

-

No. of Blocks

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

-

Retainer

-

Block Mounting Hole Pitch (Width Direction)(mm)

-

Block Mounting Hole Pitch (Length Direction)(mm)

-

Block Mounting Hole Diameter

-

Rail Mounting Hole Pitch(mm)

-

Rail Mounting Hole Diameter

Narrow search by specifying Manufacturer

Related Categories to Standard Linear Guides

FAQ linear guide

- Question: What are standard linear guides?

- Answer: Standard linear guides come in different configurations, such as:

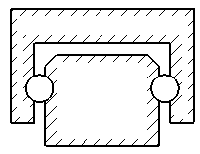

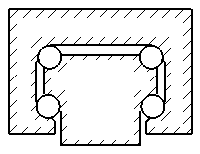

1. Profiled Rail Guides: These linear guides have a rectangular-shaped rail with a corresponding carriage. They provide high load capacity and stiffness, making them suitable for applications that require precision and rigidity.

2. Round Rail Guides: These linear guides feature a round rail and a carriage with circular-shaped rolling elements. They offer smooth and quiet motion and are commonly used in applications with lower load capacities.

3. Compact Linear Guides: These linear guides are designed to have a smaller footprint and are suitable for applications with limited space. They often feature ball bearing-based systems and are used in various industries, including automation and robotics - Question: How do standard linear guides work?

- Answer: Standard linear guides, also known as linear motion systems are mechanical devices used to provide smooth and precise linear motion in various applications. Here's a short explanation of how they work

1. Rail and Slide block: A standard linear guide consists of two main components: a rail and a slide block. The rail is a long, straight and rigid structure that serves as a guide for the linear motion. The slide block is a movable component that rides along the rail.

2. Rolling Elements: Inside the slide block, there are ball rolling. These elements reduce friction, enable smooth motion along the rail and distribute the load evenly across the rail,

3. Lubrication: Some linear guides require lubrication to further reduce friction and ensure smooth operation. Lubricants can be applied to the bearing surfaces or be pre-lubricated within the slide block.

4. Mounting: Linear guides are usually mounted to a stationary base or structure, and the slide block is connected to the moving part or load that needs linear motion. - Question: What industries use standard linear guides?

- Answer: Standard linear guides, which provide precise linear motion control, are utilized in several industries such as

1. Manufacturing and Automation: These kinds of industries widely employ standard linear guides for accurate linear motion control in machine tools, assembly lines, conveyors, and robotic systems

2. Electronics and Semiconductor Industries: The semiconductor and electronics industries rely on linear guides for precise linear motion in equipment such as wafer handling systems, semiconductor manufacturing machines, electronic assembly lines, and so on

3. Medical Industries: Linear guides are used in medical and laboratory equipment for precise linear motion control in kinds of these machines such as surgical robots, measurement tools, and laboratory automation.

4. Printing industry: The printing industry utilizes linear guides to facilitate precise linear motion control in printing machinery systems such as paper handling systems, and paper converting equipment, ensuring high-quality printing and accurate paper handling. - Question: What are the benefits of using standard linear guides?

- Answer: By using standard linear guides offers several benefits in applications requiring precise linear motion control.

1. Precise Linear Motion Control

2. Smooth and Low-Friction Operation

3. High Load-Carrying Capacity

4. Repeatability and Positioning Accuracy

5. Enhanced System Stability

6. Durability and Longevity

7. Versatile and Customizable

8. Wide Range of Applications By utilizing standard linear guides, users can achieve precise, smooth, and reliable linear motion control in their designs, enhancing system performance, accuracy, and overall productivity in numerous applications. - Question: How to select the right standard linear guide for a specific application?

- Answer: Selecting the right standard linear guide for a specific application involves considering various factors. Here's a short step by step for selecting the linear guide

1. Load Capacity: Determine the maximum load the linear guide needs to support in the application. Consider both static and dynamic loads to ensure the guide can handle the required weight.

2. Travel Distance: Evaluate the required travel distance or stroke length of the linear motion and range of motion without exceeding its limits.

3. Precision Requirements: Assess the level of precision needed for the application. Consider factors such as positioning accuracy, repeatability, and smoothness of motion.

4. Speed and Acceleration: Determine the desired speed and acceleration of the linear motion.

5. Environmental Factors: Consider factors such as temperature, humidity, dust, and exposure to chemicals.

6. Mounting and Integration: Consider the mounting options and requirements for integrating the linear guide into the application.

7. Maintenance and Lubrication: Consider factors such as ease of maintenance, lubrication intervals, and access to lubrication points.

8. Budget and Cost Considerations: Evaluate the budget available for the linear guide

9. Consult Manufacturer's Recommendations: Review the manufacturer's specifications, guidelines, and recommendations for the specific linear guide models.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy