(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 24/11/2024 to 4:30 (IST) 25/11/2024. We apologize for the inconvenience.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

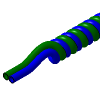

CHIYODA Air Tube/Nylon Tube(Color:Gray)

CHIYODA offers products Air Tube/Nylon Tube specified by Color Gray from Automation Components product category. There are a total of 1 items. Search and select detailed specifications of parts for your machine with free CAD downloads. CHIYODA products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

CHIYODA

A high-repulsion spiral hose that prevents sagging.

Outer Dia. D(Ø) Inner Dia. d(Ø) Material Applicable Fluid Color Type Operating Environment O.D. [Distinction] Cutting Service Usage Material: Nylon I.D. [Distinction] Material, Fluororesin Material, Urethane Number of Core(Core) Types of Related components 8 5 Urethane Air Gray Coil Standard / Water Resistance / Vacuum / Abrasion Resistance / Oil Resistance ~8 No - ~5 - Polyurethane 1 - Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Outer Dia. D(Ø) |

| Inner Dia. d(Ø) |

| Material |

| Applicable Fluid |

| Color |

| Type |

| Operating Environment |

| O.D. [Distinction] |

| Cutting Service Usage |

| Material: Nylon |

| I.D. [Distinction] |

| Material, Fluororesin |

| Material, Urethane |

| Number of Core(Core) |

| Types of Related components |

You can add up to 6 items per a category to the compare list. | |

| Brand | CHIYODA |

| Product Series | |

| From | - |

| Days to Ship | 6 Day(s) or more |

| Outer Dia. D(Ø) | 8 |

| Inner Dia. d(Ø) | 5 |

| Material | Urethane |

| Applicable Fluid | Air |

| Color | Gray |

| Type | Coil |

| Operating Environment | Standard / Water Resistance / Vacuum / Abrasion Resistance / Oil Resistance |

| O.D. [Distinction] | ~8 |

| Cutting Service Usage | No |

| Material: Nylon | - |

| I.D. [Distinction] | ~5 |

| Material, Fluororesin | - |

| Material, Urethane | Polyurethane |

| Number of Core(Core) | 1 |

| Types of Related components | - |

Loading...

Configure

Specification/Dimensions

-

Outer Dia. D(Ø)

-

Inner Dia. d(Ø)

-

Material

- Urethane

- Nylon

- Fluororesin

- Polyamide

- Fluororubber

- Silicon Rubber

- Polyolefin Resin

- Others

- PVC

- Nylon/Fluoropolymer

-

Applicable Fluid

- Water

- Air

- Chemical

- General Hydraulic Oil

- Thermal Media Oil

- Vacuum

-

Color

- Black

- White

- Milky White

- Transparent (including non-white colors)

- Red

- Blue

- Yellow

- Green

- Orange

- Ocher

- Gray

- Multi Color

- Pink

- Others

- Purple

-

Type

-

Operating Environment

- Standard

- Clean Environment

- Corrosion Resistant

- Antistatic

- Sputtering Resistant

- Mold Cooling

- Water Resistance

- Pressure Resistance

- Vacuum

- Heat Resistance

- Abrasion Resistance

- Oil Resistance

- low temperature resistance

- Weather Resistance

- Chemical Resistance

-

O.D. [Distinction]

-

Cutting Service Usage

- Yes

- No

-

Material: Nylon

-

I.D. [Distinction]

-

Material, Fluororesin

-

Material, Urethane

-

Number of Core(Core)

-

Types of Related components

Narrow search by specifying Manufacturer

-

- MISUMI (0)

- TRUSCO NAKAYAMA (3)

- CHIYODA (1)

- PISCO (1)

- MUROMOTO TEKKO (0)

- MIRUC OPTICAL (0)

- YODOGAWA (0)

- IFIELD (0)

- CHUKOH (0)

- TAIYO (0)

- AOI (0)

- NICHIAS (0)

- IWATA MFG (0)

- NITTA (0)

- ESCO (0)

- CKD (0)

- JUNKOSHA (0)

Related Categories to Air Tube/Nylon Tube

FAQ Air Tube and Nylon Tube

- Question: What are air tubes made of?

- Answer: Common air tube materials include:

Silicone: flexible, long-lasting, and resistant to kinking. Often used in aquariums and for delicate applications.

Polyurethane (PU): tougher and more resistant to heat and chemicals than silicone. Frequently used in pneumatic systems and industrial settings.

Rubber: Affordable and widely available, but not as durable as other options. - Question: What are the applications of polyurethane tube?

- Answer: Polyurethane tubes are used in a wide range of applications across various industries. They find particular use in industries such as the automotive industry, robotics and automation, industrial machinery, and the food and beverage industry. In pneumatic systems, they are utilized to connect pneumatic equipment, including air fittings, air guns, directional control valves, and more. Additionally, polyurethane tubes serve multiple purposes, such as fluid transfer, vacuum systems, agricultural equipment, medical equipment, HVAC systems, and more.

- Question: What are the benefits of using polyurethane rubber hoses?

- Answer: The benefits of using polyurethane rubber hoses include:

1. Flexibility: Polyurethane hoses are highly flexible, making them easy to handle, install, and maneuver in tight spaces.

2. Durability: They are resistant to abrasion, impact, and tearing, resulting in longer service life and reduced maintenance costs.

3. Chemical Resistance: Polyurethane hoses exhibit good resistance to a wide range of chemicals, including oils, fuels, solvents, and many gases.

4. High Strength: Despite their flexibility, they have high tensile strength and can withstand high pressures without deformation.

5. Lightweight: Polyurethane hoses are lightweight, which improves handling and reduces the overall weight of the system.

6. Temperature Resistance: They can withstand a wide temperature range, enabling their use in both high-temperature and low-temperature applications.

7. UV Resistance: Many polyurethane hoses have good resistance to ultraviolet (UV) radiation, making them suitable for outdoor applications.

8. Versatility: Polyurethane hoses can be used in various industries and applications, including pneumatic systems, fluid transfer, vacuum systems, and more.

9. Reduced Noise: They have excellent noise-damping properties, reducing the noise level in pneumatic systems and improving workplace comfort. - Question: What are the difference between Polyurethane vs. traditional rubber hoses?

- Answer: 1. Material: Polyurethane hoses are made from thermoplastic polyurethane (TPU), while traditional rubber hoses are made from natural or synthetic rubber.

2. Flexibility: Polyurethane hoses are more flexible and can be bent without kinking, while traditional rubber hoses are less flexible.

3. Abrasion Resistance: Polyurethane hoses have excellent abrasion resistance, while traditional rubber hoses are generally less resistant to abrasion.

4. Chemical Compatibility: Polyurethane hoses have better chemical resistance, while traditional rubber hoses may have limitations in certain chemical applications.

5. Temperature Range: Polyurethane hoses have a wider temperature range, while traditional rubber hoses may have limitations at extreme temperatures.

6. Weight: Polyurethane hoses are lighter in weight compared to traditional rubber hoses.

7. Cost: traditional rubber hoses are typically more cost-effective than polyurethane hoses.

Remember that specific properties can vary based on manufacturer and application, so it's always a good idea to consult product specifications for accurate information. - Question: How to choose the right polyurethane hose for your application?

- Answer: Here are some factors to consider when choosing the right polyurethane tube for your application:

1. Pressure rating: The pressure rating of the tube must be higher than the pressure of the fluid or gas that will be flowing through it.

2. Temperature range: The tube must be able to withstand the temperature of the fluid or gas that will be flowing through it.

3. Chemical resistance: The tube must be resistant to the chemicals that will be flowing through it.

4. Flexibility: The tube must be flexible enough to accommodate the bends and curves in your application.

5. Tensile strength: The tube must be strong enough to withstand the forces that will be exerted on it.

6. Weight: The weight of the tube is important if you need to move it around or install it in a difficult location.

7. Cost: The cost of the tube is an important factor to consider, especially if you need a large quantity of it.

1. Pressure rating: The pressure rating of the tube must be higher than the pressure of the fluid or gas that will be flowing through it.

2. Temperature range: The tube must be able to withstand the temperature of the fluid or gas that will be flowing through it.

3. Chemical resistance: The tube must be resistant to the chemicals that will be flowing through it.

4. Flexibility: The tube must be flexible enough to accommodate the bends and curves in your application.

5. Tensile strength: The tube must be strong enough to withstand the forces that will be exerted on it.

6. Weight: The weight of the tube is important if you need to move it around or install it in a difficult location.

7. Cost: The cost of the tube is an important factor to consider, especially if you need a large quantity of it.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy