(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Chamfering / Centering Tools(Single blade, two blades:Single blade Page5)

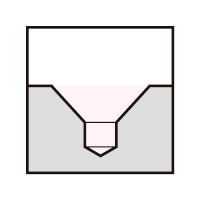

Chamfering/countersinking tools are tools used for grinding center holes, positioning holes, grinding holes, or deburring and rounding the edges after side-surface machining. They are attached to machine tools such as drill press, lathe, machining center, etc. Center drills are used to position the initial indentatio

Chamfering/countersinking tools are tools used for grinding center holes, positioning holes, grinding holes, or deburring and rounding the edges after side-surface machining. They are attached to machine tools such as drill press, lathe, machining center, etc. Center drills are used to position the initial indentation on the work material to avoid misalignment of the drill bit tip. Their materials include alloy carbide, powdered high-speed steel, cobalt high-speed steel and high-speed steel. Countersinking and chamfering cutters are capable of chamfering after drilling holes. Chamfering cutters with a hole on the tip allow for smooth cutting discharge on soft work materials such as copper and aluminum. Center drills have a 90° tip angle and they can be used for positioning and chamfering at the same time.

Search by specifying the lower class category

Centering/Countersink

Centering/Countersink Chamfer, V-Grooves

Chamfer, V-Grooves Inner R

Inner R Replaceable Blade Type Chamfering Tools/Tips/Blades

Replaceable Blade Type Chamfering Tools/Tips/Blades

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

241 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

GUHRING

[Features]

· Allows simultaneous centering and chamfering.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 10 ~ 12.7 90 Centering (Positioning) / Hole Chamfer general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 2,847.53 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

GUHRING

Allows simultaneous centering and chamfering. FIRE coating enables high-speed machining with a long service life.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 12.7 90 Centering (Positioning) / Hole Chamfer general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available Other - From: ₹ 6,000.45 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

GUHRING

Allows simultaneous centering and chamfering. FIRE coating enables high-speed machining with a long service life.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 5 ~ 20 90 Centering (Positioning) / Hole Chamfer general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available Other - From: ₹ 6,631.31 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

GUHRING

Allows simultaneous centering and chamfering. Cobalt HSS boasts excellent heat and abrasion resistance.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 3 ~ 20 90 Centering (Positioning) / Hole Chamfer general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 2,599.73 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NC Spotting Drill Long Shank 90° 559

GUHRING

Deep part centering and chamfering of the workpiece can be done at the same time.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 15.87 90 Centering (Positioning) / Hole Chamfer general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 7,039.82 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Straight Shank, Countersink 3-Flute 60° 472

GUHRING

Has 3 cutting edges for excellent cutting balance, enabling highly circular, stable chamfering and deburring with little chatter.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 6.3 ~ 25 60 Hole Chamfer general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 1,784.04 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Straight Shank, Countersink 3-Flute, 90° (Set of 327) 499

GUHRING

[Features]

· 6-piece set of 327.

· Steel case provided.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 6.30/8.30/10.40/12.40/16.50/20.50 90 - general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiN - From: ₹ 26,635.16 Days to Ship: 23 Day(s) or more  23 Day(s) or more

23 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Straight Shank, Countersink 3-Flute, 90° (Set of 476) 498

GUHRING

[Features]

· 6-piece set of 476.

· Steel case provided.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 6.30/8.30/10.40/12.40/16.50/20.50 90 - general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 79,999.20 Days to Ship: 24 Day(s) or more  24 Day(s) or more

24 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Straight Shank, Countersink, Multi Blade 90° 474

GUHRING

Adopts multiple blades to achieve a clean machined surface free of burrs.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 8 ~ 20 90 Hole Chamfer general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 1,518.84 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Tapered Shank Countersink, 3-Flute 60° 473

GUHRING

Has 3 cutting edges for excellent cutting balance, enabling highly circular, stable chamfering and deburring with little chatter.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 16 ~ 80 60 Hole Chamfer general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 5,271.82 Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Tapered Shank Countersink, 3-Flute 90° 328

GUHRING

Has 3 cutting edges for excellent cutting balance, enabling highly circular, stable chamfering and deburring with little chatter. Long product life with TiN coating.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 25 ~ 50 90 Hole Chamfer general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiN - From: ₹ 11,992.91 Days to Ship: 23 Day(s) or more  23 Day(s) or more

23 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Tapered Shank Countersink, 3-Flute 90° 477

GUHRING

Has 3 cutting edges for excellent cutting balance, enabling highly circular, stable chamfering and deburring with little chatter.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 15 ~ 100 90 Hole Chamfer general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 5,424.51 Days to Ship: 23 Day(s) or more  23 Day(s) or more

23 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

GUHRING

[Features]

· A deburring fork for chamfering and deburring of hole entrances and exits.

· Internal oil supply type.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide - - Hole Chamfer general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 65,355.69 Days to Ship: 24 Day(s) or more  24 Day(s) or more

24 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

GUHRING

Capable of chamfering and deburring of hole entrances and exits by milling.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 12 90 Hole Chamfer general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: ₹ 8,712.73 Days to Ship: 24 Day(s) or more  24 Day(s) or more

24 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NC Starting Drills for Center Positioning (125°)_NC-SD

YAMAWA MFG

Features a high-rigidity design that enables stable and accurate positioning and chamfering. Effective for positioning otherwise difficult to machine curved surfaces and gentle slopes thanks to the good chamfering property.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - 5 125° Centering (Positioning) / Hole Chamfer - Single blade NA NA - - From: ₹ 1,450.69 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NC Starting Drills for Chamfering (90°), Coated_NC-SD-V

YAMAWA MFG

A drill for chamfering the end face after drilling with a drill.

[Features]

· Adopts cobalt high-speed steel with excellent wear resistance.

[Applications]

· By using NC-SD V, larger than the diameter after hole drilling, cleanly-finished chamfered surfaces can be achieved.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 5 90° Centering (Positioning) / Hole Chamfer - Single blade NA Available TiN - From: ₹ 1,973.05 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Countersinks 90°, Machining Center Use_CS-Q

YAMAWA MFG

Countersink that can perform high-precision chamfering of round holes and mounting surfaces of small screws and bolts.

[Features]

· It has a single blade ideal for use in machining centers.

[Applications]

· Ideal for use with NC machines and machining centers.

* Use after fixing both the tool and the workpiece.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 4 90 Hole Chamfer - Single blade NA NA - - From: ₹ 831.73 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Counter Sink 3 Flutes 90°CBN Polishing

NOGA JAPAN

[Features]

· The deep sharp blade and accurate cutting ensure high precision and excellent cutting performance.

· Recommended for steel, cast items, non-ferrous metals, and light metals.

· More effective at relatively slow cutting speeds (10 to 20 m/min).Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 4.3 ~ 31 90 - - Single blade - - - - From: ₹ 1,282.15 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NOGA JAPAN

[Features]

· Noga Titanium Coated Countersinks are made of heat-treated HSS with a CBN ground blade and titanium nitride coating.

· The deep sharp blade and accurate cutting ensure high precision and excellent cutting performance.

· Recommended for steel, cast items, non-ferrous metals, and light metals.

· More effective at relatively slow cutting speeds (10 to 20 m/min).Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel - - - general steel[○] / Cast Iron[○] Single blade - - - - From: ₹ 14,643.00 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Cobalt high-speed steel counter sink (Co5), 3-fluted, 90°, CBN polish

NOGA JAPAN

[Features]

· Noga Titanium Coated Countersinks are made of heat-treated HSS with a CBN ground blade and titanium nitride coating.

· The deep sharp blade and accurate cutting ensure high precision and excellent cutting performance.

· Recommended for steel, cast items, non-ferrous metals, and light metals.

· More effective at relatively slow cutting speeds (10 to 20 m/min).Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 6.3 ~ 31 90 - Stainless Steel[○] Single blade - - - - From: ₹ 2,125.96 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Titanium Coated Countersink 3 Flute Blade 90° CBN Polish

NOGA JAPAN

[Features]

· Noga Titanium Coated Countersinks are made of heat-treated HSS with a CBN ground blade and titanium nitride coating.

· The deep sharp blade and accurate cutting ensure high precision and excellent cutting performance.

· Recommended for steel, cast items, non-ferrous metals, and light metals.

· More effective at relatively slow cutting speeds (10 to 20 m/min).Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 6.3 ~ 31 90 - - Single blade - Available TiN - From: ₹ 2,247.85 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Titanium Coated Countersink Set

NOGA JAPAN

[Features]

· Noga Titanium Coated Countersinks are made of heat-treated HSS with a CBN ground blade and titanium nitride coating.

· The deep sharp blade and accurate cutting ensure high precision and excellent cutting performance.

· Recommended for steel, cast items, non-ferrous metals, and light metals.

· More effective at relatively slow cutting speeds (10 to 20 m/min).Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel - - - - Single blade - Available TiN - From: ₹ 19,903.80 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide Chamfering Cutter KMC-2

KYOWA SEIKO

[Applications]It can be used for chamfering and horizontal machining. [Features]By using carbide materials with high hardness, it can be used for cutting general steel, heat-treated steel, stainless steel, cast iron, and aluminum.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.3 ~ 4 90° Chamfering/Horizontal general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] Single blade - NA - - From: ₹ 3,217.20 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide Inversed Chamfering Cutter KUMC-4

KYOWA SEIKO

4 straight flutes.

45° (single angle type)

Work Material, General Steel/Heat-Treated Steel/Stainless Steel/Cast Iron/Aluminum

Single-edge blade

Tool grade, CarbideTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide - - Chamfering/Horizontal general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] Single blade - NA - - From: ₹ 8,213.13 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

CoroMill Plura - General Purpose Chamfering End Mill, Cylindrical Shank / Weldon Shank

SANDVIK

High performance end mill with high versatility

[Features]

·One end mill for all work materials

·Improved machine operating rate

·Minimize tool inventory

·Safe and predictable tool life

·High flexibility and optimized toolingTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 8 ~ 12 90° Chamfering/Horizontal general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] Single blade NA Available Other - From: ₹ 9,752.47 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Hexagonal Shank Countersink (90° Tip Angle)

RUKO

[Features]

· Hexagonal shaft (6.35 mm) shank allows easy setting for work.

· Minimizes chattering and burrs.

[Applications]

· Work materials: Iron, cast iron, non-ferrous metals, light metals.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1.5 ~ 3.5 90 Hole Chamfer general steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] Single blade Available NA Non-Coated - From: ₹ 3,227.71 Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Hexagonal Shank Countersink (90° Tip Angle, Titanium Coated)

RUKO

[Features]

· Hexagonal shaft (6.35 mm) shank allows easy setting for work.

· Minimizes chattering and burrs.

[Applications]

· Work materials: Iron, cast iron, non-ferrous metals, light metals.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1.5 ~ 3.5 90 Hole Chamfer general steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] Single blade Available Available TiN - From: ₹ 3,464.78 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

DIXI

[Features]

· Enables positioning and chamfering with only one process.

· Enables high precision positioning (center gouging), accurate positioning on curved and sloped surfaces, and high-quality chamfering (countersink).

· High-speed high feed is possible.

· Centering and chamfering are done simultaneously before tap pilot hole drilling.

[Applications]

· Work materials: Steel, alloy steel, stainless steel, cast iron, aluminum, copper, brass, plastic (nylon).

[Material]

· Carbide alloy (K20)Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - 90 ~ 120 - - Single blade - - Non-Coated - From: ₹ 3,855.13 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

OptiMill® Drill Mill (2 Flutes)

MAPAL

[Features]

· Diverse processing is possible, including positioning, drilling, chamfering, side processing, and V-grooving.

· No flat part at the tip.

[Applications]

· Work materials: Carbon steel, alloy steel, stainless steel, cast iron, light alloy.

[Material]

· Ultrafine particle carbide alloyTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - 3 ~ 16 Center Hole Angle: 90° - - Single blade - NA - - From: ₹ 3,970.31 Days to Ship: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

OptiMill® Chamfering Mill (4 Flutes)

MAPAL

[Features]

· Dedicated for chamfering.

· The 4-flute specification emphasizes efficiency.

· No flat part at the tip.

[Applications]

· Work materials: Carbon steel, alloy steel, stainless steel, cast iron, light alloy.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - Center Hole Angle: 90° - - Single blade - Available Other - From: ₹ 4,156.49 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

DAIICHITOOL

[Features]

A center reamer with an overall length of 45 to 99 mm and a handle diameter of 6 to 12 mm.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 6 ~ 50 60° ~ 90° Centering (Positioning) general steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade Available - - - From: ₹ 2,247.05 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

WATERMILLS ® 3-Flute Countersink WMC5TA 90° 5% Cobalt High-Speed Steel + TiAlN Coating

WATERMILLS

[Features]

·It has 3 flutes.

Applications: hole chamfering

tip angle (θ): 90°

Coating type: TiAINTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 4.3 ~ 31 90° Hole Chamfer - Single blade - Available TiAlN - From: ₹ 2,885.40 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

WATERMILLS ® 3-Flute Countersink WMC 90° High-Speed Steel, Long Shank Type

WATERMILLS

[Features]

·It has 3 flutes.

Applications: hole chamfering

tip angle (θ): 90°

Coating type: uncoatedTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 6.3 ~ 25 90° Hole Chamfer - Single blade - NA Non-Coated - From: ₹ 4,897.18 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

WATERMILLS ® 1-Flute Countersink WMSFC 90° for Drill, Chamfer, for Veneer

WATERMILLS

New at MISUMI? Get 20% Discount on your First Purchase. Click to Register Now

[Materials]·5% cobalt high-speed steel.

Applications: hole chamfering

tip angle (θ): 90°

Coating type: uncoated

Overall length (mm): 78 (±)Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 25.0(+0.3) 90° Hole Chamfer - Single blade - NA Non-Coated - From: ₹ 4,800.75 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

WXL-Coated Chamfering Cutter Negative Type Regular W-HSCT-N

OSG

[Features]

· A unique 3-flute specification which helps prevent cracking during machining and which enables high-efficiency and high-feed machining.

The 40° torsion and wide tip pockets enable both excellent cutting performance and high level surface finishing.

Significantly reduces turning-back, or burring.

Excellent chip discharge.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide - 90° Chamfering/Horizontal general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] Single blade NA Available - - From: ₹ 9,153.76 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Standard Type, Non-Coating Series MVS 60°

MAKOTOLOY

[Features]

·1 pc. of V-cut end mill can be used for various purposes such as centering countersinking, inner chamfering, outer peripheral chamfering, side machining, V-groove, drilling, and is ideal for MC and NC machining

·Since the cutting tip is close to the V edge, the residue on the bottom during V-groove machining is very few

·Since it is based on a carbide end mill with a right blade and a right twist of 30°, the sharpness is one of the best and the discharge of cutting chips is also good

·Since the ultra-fine carbide alloy is used as the carbide material, it has a lifespan approx. 10 times longer than that of HSS end mill. Furthermore, the V-cut end mill coating series has a long lifespan and increases cutting speed to shorten machining time

・ Standard typeTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 20 60 Hole Chamfer / Chamfering/Horizontal general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 8,389.02 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Standard Type, Non-Coating Series MVS 120°

MAKOTOLOY

[Features]

· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.

· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.

· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.

· An ultra-fine particle carbide alloy is used for the carbide material, ensuring a long tool life.

· Standard type.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 20 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 8,389.02 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 60°

MAKOTOLOY

[Features]

· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.

· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.

· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.

· An ultra-fine particle carbide alloy is used for the carbide material.

· Long tool life, improved cutting speed and reduced machining time.

· Standard type.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 20 60 Hole Chamfer / Chamfering/Horizontal general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: ₹ 11,203.09 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 120°

MAKOTOLOY

[Features]

· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.

· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.

· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.

· An ultra-fine particle carbide alloy is used for the carbide material.

· Long tool life, improved cutting speed and reduced machining time.

· Standard type.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 20 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: ₹ 11,203.09 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 60°

MAKOTOLOY

[Features]

· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.

· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.

· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.

· An ultra-fine particle carbide alloy is used for the carbide material, ensuring a long tool life.

· Long type.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 60 Hole Chamfer / Chamfering/Horizontal general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 9,909.71 Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 90°

MAKOTOLOY

[Features]

· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.

· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.

· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.

· An ultra-fine particle carbide alloy is used for the carbide material, ensuring a long tool life.

· Long type.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 9,909.71 Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 120°

MAKOTOLOY

[Features]

· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.

· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.

· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.

· An ultra-fine particle carbide alloy is used for the carbide material, ensuring a long tool life.

· Long type.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: ₹ 9,909.71 Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Long Type, Coated Series AMVL 60°

MAKOTOLOY

[Features]

· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.

· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.

· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.

· An ultra-fine particle carbide alloy is used for the carbide material.

· Long tool life, improved cutting speed and reduced machining time.

· Long type.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 60 Hole Chamfer / Chamfering/Horizontal general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: ₹ 11,904.04 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Long Type, Coated Series AMVL 90°

MAKOTOLOY

[Features]

· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.

· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.

· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.

· An ultra-fine particle carbide alloy is used for the carbide material.

· Long tool life, improved cutting speed and reduced machining time.

· Long type.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: ₹ 11,904.04 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide V Cut End Mill Long Type Coated Series AMVL 120°

MAKOTOLOY

[Features]

· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.

· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.

· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.

· An ultra-fine particle carbide alloy is used for the carbide material.

· Long tool life, improved cutting speed and reduced machining time.

· Long type.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: ₹ 11,904.04 Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Tool Material Type |

| Tool Diameter (D)(mm) |

| Tip angle (θ) |

| Application |

| work material |

| Single blade, two blades |

| Peripheral Blade Y/N |

| Coating Y/N |

| Coating Type |

| R Size (R)(mm) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | GUHRING | GUHRING | GUHRING | GUHRING | GUHRING | GUHRING | GUHRING | GUHRING | GUHRING | GUHRING | GUHRING | GUHRING | GUHRING | GUHRING | YAMAWA MFG | YAMAWA MFG | YAMAWA MFG | NOGA JAPAN | NOGA JAPAN | NOGA JAPAN | NOGA JAPAN | NOGA JAPAN | KYOWA SEIKO | KYOWA SEIKO | SANDVIK | RUKO | RUKO | DIXI | MAPAL | MAPAL | DAIICHITOOL | WATERMILLS | WATERMILLS | WATERMILLS | OSG | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY |

| Product Series | Cobalt high-speed steel counter sink (Co5), 3-fluted, 90°, CBN polish | CoroMill Plura - General Purpose Chamfering End Mill, Cylindrical Shank / Weldon Shank | Hexagonal Shank Countersink (90° Tip Angle, Titanium Coated) | WATERMILLS ® 3-Flute Countersink WMC5TA 90° 5% Cobalt High-Speed Steel + TiAlN Coating | WATERMILLS ® 3-Flute Countersink WMC 90° High-Speed Steel, Long Shank Type | WATERMILLS ® 1-Flute Countersink WMSFC 90° for Drill, Chamfer, for Veneer | V-Cut Carbide End Mills, Standard Type, Non-Coating Series MVS 60° | V-Cut Carbide End Mills, Standard Type, Non-Coating Series MVS 120° | V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 60° | V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 120° | V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 60° | V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 90° | V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 120° | ||||||||||||||||||||||||||||||||

| CAD | |||||||||||||||||||||||||||||||||||||||||||||

| From | ₹ 2,847.53 | ₹ 6,000.45 | ₹ 6,631.31 | ₹ 2,599.73 | ₹ 7,039.82 | ₹ 1,784.04 | ₹ 26,635.16 | ₹ 79,999.20 | ₹ 1,518.84 | ₹ 5,271.82 | ₹ 11,992.91 | ₹ 5,424.51 | ₹ 65,355.69 | ₹ 8,712.73 | ₹ 1,450.69 | ₹ 1,973.05 | ₹ 831.73 | ₹ 1,282.15 | ₹ 14,643.00 | ₹ 2,125.96 | ₹ 2,247.85 | ₹ 19,903.80 | ₹ 3,217.20 | ₹ 8,213.13 | ₹ 9,752.47 | ₹ 3,227.71 | ₹ 3,464.78 | ₹ 3,855.13 | ₹ 3,970.31 | ₹ 4,156.49 | ₹ 2,247.05 | ₹ 2,885.40 | ₹ 4,897.18 | ₹ 4,800.75 | ₹ 9,153.76 | ₹ 8,389.02 | ₹ 8,389.02 | ₹ 11,203.09 | ₹ 11,203.09 | ₹ 9,909.71 | ₹ 9,909.71 | ₹ 9,909.71 | ₹ 11,904.04 | ₹ 11,904.04 | ₹ 11,904.04 |

| Days to Ship | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 6 Day(s) or more | 7 Day(s) or more | 5 Day(s) or more | 23 Day(s) or more | 24 Day(s) or more | 5 Day(s) or more | 8 Day(s) or more | 23 Day(s) or more | 23 Day(s) or more | 24 Day(s) or more | 24 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 7 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 7 Day(s) or more | 5 Day(s) or more | 8 Day(s) or more | 6 Day(s) or more | 5 Day(s) or more | 9 Day(s) or more | 5 Day(s) or more | 7 Day(s) or more | 7 Day(s) or more | 7 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 6 Day(s) or more | 7 Day(s) or more | 7 Day(s) or more | 7 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 5 Day(s) or more | 7 Day(s) or more | 8 Day(s) or more |

| Tool Material Type | High-speed steel | High-speed steel | Carbide | Cobalt HSS | High-speed steel | High-speed steel | High-speed steel | High-speed steel | High-speed steel | High-speed steel | High-speed steel | High-speed steel | Carbide | Carbide | - | Cobalt HSS | High-speed steel | High-speed steel | High-speed steel | Cobalt HSS | High-speed steel | High-speed steel | Carbide | Carbide | Carbide | High-speed steel | High-speed steel | - | - | - | High-speed steel | Cobalt HSS | High-speed steel | Cobalt HSS | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide |

| Tool Diameter (D)(mm) | 10 ~ 12.7 | 12.7 | 5 ~ 20 | 3 ~ 20 | 15.87 | 6.3 ~ 25 | 6.30/8.30/10.40/12.40/16.50/20.50 | 6.30/8.30/10.40/12.40/16.50/20.50 | 8 ~ 20 | 16 ~ 80 | 25 ~ 50 | 15 ~ 100 | - | 3 ~ 12 | 5 | 5 | 4 | 4.3 ~ 31 | - | 6.3 ~ 31 | 6.3 ~ 31 | - | 0.3 ~ 4 | - | 8 ~ 12 | 1.5 ~ 3.5 | 1.5 ~ 3.5 | - | 3 ~ 16 | - | 6 ~ 50 | 4.3 ~ 31 | 6.3 ~ 25 | 25.0(+0.3) | - | 1 ~ 20 | 1 ~ 20 | 1 ~ 20 | 1 ~ 20 | 3 ~ 20 | 3 ~ 20 | 3 ~ 20 | 3 ~ 20 | 3 ~ 20 | 3 ~ 20 |

| Tip angle (θ) | 90 | 90 | 90 | 90 | 90 | 60 | 90 | 90 | 90 | 60 | 90 | 90 | - | 90 | 125° | 90° | 90 | 90 | - | 90 | 90 | - | 90° | - | 90° | 90 | 90 | 90 ~ 120 | Center Hole Angle: 90° | Center Hole Angle: 90° | 60° ~ 90° | 90° | 90° | 90° | 90° | 60 | 120 | 60 | 120 | 60 | 90 | 120 | 60 | 90 | 120 |

| Application | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Hole Chamfer | - | - | Hole Chamfer | Hole Chamfer | Hole Chamfer | Hole Chamfer | Hole Chamfer | Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Hole Chamfer | - | - | - | - | - | Chamfering/Horizontal | Chamfering/Horizontal | Chamfering/Horizontal | Hole Chamfer | Hole Chamfer | - | - | - | Centering (Positioning) | Hole Chamfer | Hole Chamfer | Hole Chamfer | Chamfering/Horizontal | Hole Chamfer / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Hole Chamfer / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Hole Chamfer / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Hole Chamfer / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling |

| work material | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | - | - | - | - | general steel[○] / Cast Iron[○] | Stainless Steel[○] | - | - | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] | general steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] | general steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] | - | - | - | general steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | - | - | - | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] |

| Single blade, two blades | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade |

| Peripheral Blade Y/N | - | - | - | - | - | - | - | - | - | - | - | - | - | - | NA | NA | NA | - | - | - | - | - | - | - | NA | Available | Available | - | - | - | Available | - | - | - | NA | - | - | - | - | - | - | - | - | - | - |

| Coating Y/N | NA | Available | Available | NA | NA | NA | Available | NA | NA | NA | Available | NA | NA | Available | NA | Available | NA | - | - | - | Available | Available | NA | NA | Available | NA | Available | - | NA | Available | - | Available | NA | NA | Available | NA | NA | Available | Available | NA | NA | NA | Available | Available | Available |

| Coating Type | - | Other | Other | - | - | - | TiN | - | - | - | TiN | - | - | TiAlN | - | TiN | - | - | - | - | TiN | TiN | - | - | Other | Non-Coated | TiN | Non-Coated | - | Other | - | TiAlN | Non-Coated | Non-Coated | - | - | - | TiAlN | TiAlN | - | - | - | TiAlN | TiAlN | TiAlN |

| R Size (R)(mm) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Tool Material Type

-

Tool Diameter (D)(mm)

- 0 to 2

- 0.02

- 0.03

- 0.04

- 0.05

- 0.06

- 0.07

- 0.08

- 0.09

- 0.1

- 0.11

- 0.12

- 0.13

- 0.14

- 0.15

- 0.16

- 0.17

- 0.18

- 0.19

- 0.2

- 0.21

- 0.22

- 0.23

- 0.24

- 0.25

- 0.26

- 0.27

- 0.28

- 0.29

- 0.3

- 0.3, 0.6

- 0.35

- 0.4

- 0.45

- 0.45~2.1

- 0.45~2.7

- 0.5

- 0.5, 1

- 0.55

- 0.6

- 0.65

- 0.65~2.1

- 0.65~2.7

- 0.7

- 0.75

- 0.8

- 0.85

- 0.9

- 0.95

- 1

- 1, 2

- 1–6

- 1/8

- 1/16

- 1/32

- 1/64

- 1.1

- 1.2

- 1.25

- 1.3

- 1.4

- 1.5

- 1.6

- 1.7

- 1.8

- 1.9

- 2.

- 2

- 2–10

- 2~13

- 2.1

- 2.2

- 2.3

- 2.4

- 2.5

- 2.6

- 2.7

- 2.8

- 2.9

- 3

- 3~14

- 3 to 15

- 3/16

- 3/32

- 3/64

- 3.1

- 3.15

- 3.2

- 3.4

- 3.5

- 3.6

- 3.8

- 4

- 4.2

- 4.3

- 4.4

- 4.5

- 4.6

- 4.8

- 5

- 5/16

- 5/32

- 5/64

- 5.1

- 5.2

- 5.3

- 5.4

- 5.5

- 5.6

- 5.8

- 6

- 6.2

- 6.3

- 6.3,8.3,10.4,12.4,16.5,20.5

- 6.30/8.30/10.40/12.40/16.50/20.50

- 6.3/8.3/10.4/12.4/16.5/20.5

- 6.35

- 6.4

- 6.5

- 6.6

- 6.8

- 7

- 7.2

- 7.3

- 7.4

- 7.5

- 7.6

- 7.7

- 7.8

- 8

- 8.2

- 8.3

- 8.4

- 8.8

- 9

- 9.1

- 9.4

- 9.5

- 9.52

- 10

- 10.1

- 10.3

- 10.4

- 10.5

- 10.8

- 11

- 11.1

- 11.4

- 11.5

- 11.88

- 12

- 12.1

- 12.3

- 12.4

- 12.5

- 12.7

- 13

- 13.4

- 13.5

- 14

- 14.2

- 14.4

- 14.5

- 14.6

- 15

- 15.1

- 15.2

- 15.4

- 15.5

- 15.6

- 15.87

- 16

- 16.15

- 16.3

- 16.5

- 16.5,20.5,25.0,37.0

- 17

- 17.1

- 17.7

- 18

- 18.2

- 18.5

- 18.6

- 19

- 19.05

- 19.5

- 20

- 20.5

- 21

- 21.5

- 21.77

- 22

- 22.3

- 22.5

- 23

- 23.4

- 24

- 25

- 25.0(+0.3)

- 25.20

- 25.3

- 26

- 26.6

- 27

- 28

- 29

- 29.9

- 30

- 30.20

- 30.5

- 31

- 31.5

- 31.7

- 31.9

- 32

- 32.6

- 32.7

- 33.1

- 33.3

- 34

- 34.1

- 34.8

- 34.9

- 35

- 35.4

- 35.9

- 36

- 36.9

- 37

- 37.1

- 37.9

- 38

- 39

- 39.83

- 40

- 43

- 45

- 45.6

- 46

- 48

- 49.85~134.6

- 50

- 50.7

- 52.8

- 53.6

- 53.91

- 54.3

- 55

- 56

- 56.8

- 57.0

- 57.9

- 58.2

- 60

- 61.4

- 62.2

- 63

- 64.6

- 65

- 66

- 67.4

- 67.94

- 69.2

- 69.8

- 70

- 71.8

- 73.3

- 75

- 80

- 90

- 95

- 100

-

Tip angle (θ)

-

Application

-

work material

-

Single blade, two blades

-

Peripheral Blade Y/N

-

Coating Y/N

-

Coating Type

-

R Size (R)(mm)

- 0.1

- 0.15

- 0.2

- 0.25

- 0.3

- 0.35

- 0.4

- 0.45

- 0.5

- R0.5

- 0.5/1/1.5/2

- 0.5 to 4

- 0.5~5

- 0.55

- 0.6

- 0.65

- 0.7

- 0.75

- R0.75

- 0.8

- 0.85

- 0.9

- 0.95

- 1

- 1RM

- 1RY

- R1

- 1, 1.5

- 1/2/3/4

- 1–3

- 1–5

- 1.05

- 1.1

- 1.15

- 1.2

- 1.25

- R1.25

- 1.3

- 1.35

- 1.4

- 1.45

- 1.5

- R1.5

- 1.55

- 1.6

- 1.65

- 1.7

- 1.75

- 1.8

- 1.85

- 1.9

- 1.95

- 2

- 2RM

- 2RY

- R2

- 2, 3

- 2.05

- 2.1

- 2.15

- 2.2

- 2.25

- 2.3

- 2.35

- 2.4

- 2.45

- 2.5

- R2.5

- 2.6

- 2.7

- 2.75

- 2.8

- 2.9

- 3

- 3RM

- 3RY

- R3

- 3.25

- 3.5

- R3.5

- 3.75

- 4

- 4RM

- 4RY

- R4

- 4.25

- 4.5

- R4.5

- 4.75

- 5

- 5RM

- R5

- 5–10

- 5.25

- 5.5

- 5.75

- 6

- R6

- 6.25

- 6.5

- 6.75

- 7

- R7

- 7.25

- 7.5

- 7.75

- 8

- R8

- 8.5

- 9

- R9

- 9.5

- 10

- R10

- 10.5

- 11

- 11.5

- 12

- R12

- 12.5

- R12.5

- 13

- 13.5

- 14

- 14.5

- 15

- R15

- 15.5

- 16

- R16

- 16.5

- 17

- 17.5

- 18

- 18.5

- 19

- 19.5

- 20

- 20.5

- 21

- 21.5

- 22

- 22.5

- 23

- 23.5

- 24

- 24.5

- 25

- 25.5

- 26

- 26.5

- 27

- 27.5

- 28

- 28.5

- 29

- 29.5

- 30

- XRM

- XRY

Related Categories to Chamfering / Centering Tools

-

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy