(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Specification/Dimensions

-

type

- TSC-CR-HFEM4N

-

Outer Diameter (D)(φ)

-

R Size(mm)

-

Flute Length (ℓ)(mm)

-

Overall Length (L)(mm)

-

Shank Diameter (d)(mm)

-

Length Under Neck (ℓ1)(mm)

Days to Ship

-

- All

- 6 Day(s) or Less

Specify Alterations

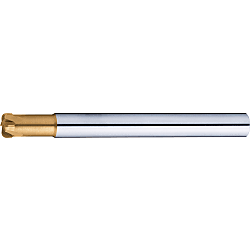

TSC series carbide radius end mill, high-feed, high-rigidity, 4-flute / no side blade (TSC-CR-HFEM4N6-R1)

- TS

- High-Hardness Steel

- 4 Flutes

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Description

[Features]

·High rigidity is achieved by adopting negative radius and short blade length without helix angle and chattering is suppressed even at pocket corners

·Since it has back taper, it is possible to perform machining without peripheral edge hitting side when machining corners

·Even for bottom surface processing, single machine can handle from middle finish to final finish, realizing reduction in process time

| Part Number |

|---|

| TSC-CR-HFEM4N6-R1 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | Outer Diameter (D) (φ) | R Size (mm) | Flute Length (ℓ) (mm) | Overall Length (L) (mm) | Shank Diameter (d) (mm) | Length Under Neck (ℓ1) (mm) | Under Neck Diameter d1 (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

₹ 3,898.65 | 1 Piece(s) | 6 Day(s) or more | 6 | 1 | 2.5 | 90 | 6 | 12 | 5.4 |

Loading...

Specifications

| Model Number | Flute Length ℓ |

Under Neck Diameter d1 |

Length Under Neck ℓ1 |

Overall Length L |

Shank Diameter d |

Figure | |||||||

| Outer Diameter D |

Radius R (Selection) |

||||||||||||

| TSC-CR-HFEM4N | 3 | 0.75 | 1.2 | 2.7 | 7.5 | 60 | 6 | 1 | |||||

| 4 | 1 | 1.6 | 3.6 | 10 | 70 | 6 | 1 | ||||||

| 5 | 1.2 | 2 | 4.5 | 12 | 80 | 6 | 1 | ||||||

| 6 | 1 | 1.5 | 2.5 | 5.4 | 12 | 90 | 6 | 2 | |||||

| 8 | 1 | 2 | 3.5 | 7.2 | 16 | 100 | 8 | 2 | |||||

| 10 | 1 | 2 | 3 | 4 | 9 | 20 | 100 | 10 | 2 | ||||

| 12 | 1 | 2 | 3 | 5 | 11 | 24 | 110 | 12 | 2 | ||||

For Cutting Conditions, Refer to >>Click here.

More Information

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, resulting in a longer operational life and ideal for high speed machining / dry machining.

● Has a negatively sharpened radius and non-twisted short blade length to realize a high rigidity and suppress chatter, even in pocket corners.

● Includes a back-taper that enables corners to be machined without the shoulder of the peripheral blade striking side surfaces.

● Just the one bit can be used for medium-finishing through to finishing with bottom surface machining, achieving a reduction in processing time.

Basic Information

| Work Material | General Steel / Heat-Treated Steel / High-Hardness Steel ~ HRC55 / High-Hardness Steel ~ HRC60 / High-Hardness Steel – HRC65 / Stainless Steel / Cast Iron | Number of Flutes(sheet) | 4 | Model | High-Feed Radius |

|---|---|---|---|---|---|

| Processing Applications | Flat Surface / Side Surface / Curved Surface / Inclined Cutting | Coating | For High Hardness (Silicone-Based) | Torsion Angle (θ) | Without Torsion |

| R Precision(μm) | ±0.02 | Additional Classification | Stocked Product |

Please check the type/dimensions/specifications of the part TSC-CR-HFEM4N6-R1 in the TSC series carbide radius end mill, high-feed, high-rigidity, 4-flute / no side blade series.

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Product variants

| Part Number |

|---|

| TSC-CR-HFEM4N12-R1 |

| TSC-CR-HFEM4N12-R2 |

| TSC-CR-HFEM4N12-R3 |

| TSC-CR-HFEM4N6-R1.5 |

| TSC-CR-HFEM4N8-R1 |

| TSC-CR-HFEM4N8-R2 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | Outer Diameter (D) (φ) | R Size (mm) | Flute Length (ℓ) (mm) | Overall Length (L) (mm) | Shank Diameter (d) (mm) | Length Under Neck (ℓ1) (mm) | Under Neck Diameter d1 (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

₹ 7,513.36 | 1 Piece(s) | 6 Day(s) or more | 12 | 1 | 5 | 110 | 12 | 24 | 11 | ||

₹ 7,499.53 | 1 Piece(s) | 6 Day(s) or more | 12 | 2 | 5 | 110 | 12 | 24 | 11 | ||

₹ 7,577.51 | 1 Piece(s) | 6 Day(s) or more | 12 | 3 | 5 | 110 | 12 | 24 | 11 | ||

₹ 4,257.22 | 1 Piece(s) | 6 Day(s) or more | 6 | 1.5 | 2.5 | 90 | 6 | 12 | 5.4 | ||

₹ 4,544.51 | 1 Piece(s) | 6 Day(s) or more | 8 | 1 | 3.5 | 100 | 8 | 16 | 7.2 | ||

₹ 5,673.29 | 1 Piece(s) | 6 Day(s) or more | 8 | 2 | 3.5 | 100 | 8 | 16 | 7.2 |

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy