(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 24/11/2024 to 4:30 (IST) 25/11/2024. We apologize for the inconvenience.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Specification/Dimensions

-

type

- E-MUITZ

- E-MUIZ

-

Inner Dia. d(Ø)

-

Outer Dia. D(Ø)

-

Overall Length L(mm)

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

Specify Alterations

Oil Free Bushings Flange Integrated Type/Embedded Flanged Type (Part Number)

- Volume Discount

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Description

- Oil Free Bushings Flange Integrated Type/Embedded Flanged Type, E-MUITZ / E-MUIZ from MISUMI.

- Recommended mating shaft for I.D. of Copper oil-free bushing are d8: General use (High Load), e7: General use (Light Load), f8: High precision use, g6: High precision use (Intermittent operation).

- The Copper oil-free bushing E-MUITZ / E-MUIZ series is made of High tensile brass alloy with solid lubricant embedded.

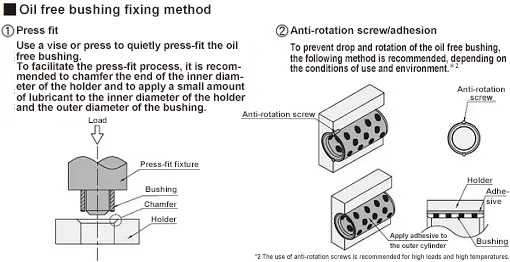

- It is recommended to fix the bushing with anti-rotation screw.

- Accessories: Low head hexagon socket head screws 2 to 4 pcs.

Dimensional Drawing of Oil Free Bushings

Recommendable Shaft of Oil Free Bushings

Recommendable Shaft of Oil Free Bushingsd8: General Use(High Load)

e7: General Use(Light Load)

f8 : High Precision Use

g6: High Precision Use (Intermittent Operation)

Material of Oil Free Bushings: High Tensile Brass Alloy

Material of Oil Free Bushings: High Tensile Brass AlloySolid Lubricant Embedded

Specification Table of Oil Free Bushings

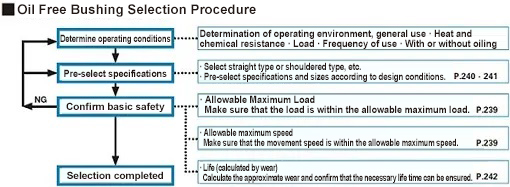

Follow the selection procedure Oil Free Bushings ~

~ to select the type and parameters before ordering.

to select the type and parameters before ordering.Part Number ( Type of Oil Free Bushings· Type of Oil Free Bushings· d) d) | - |  L L |

| E-MUITZ | - | 30 |

| Part Number of Oil Free Bushings |  Overall Length L Overall Length L | Dh7 | Da | L1 | H | T | t | d1 | d2 | P.C.D | F | A | Applicable to Hex Socket Low Head Cap Screw (not provided) | |||||||

Type of Oil Free Bushings Type of Oil Free Bushings |  I.D. dF7 I.D. dF7 | |||||||||||||||||||

| E-MUIZ (Round Flanged) E-MUITZ (Compact Flanged) | 10 | +0.028 +0.013 | 25 | 30 | 14 | 13.5 | 6 | 29 | 4 | 2.2 | 3.5 | 6 | 21 | - | 21 | M3-10 | ||||

| 12 | +0.034 +0.016 | 25 | (30) | 18 | 17.5 | 36 | 5 | 3 | 4.5 | 7.5 | 26 | 26 | M4-12 | |||||||

| 16 | 25* | 30 | 40 | 22 | 21.5 | 40 | 30 | 18 | 24 | |||||||||||

| 20 | +0.041 +0.020 | 30* | 50 | 28 | 27.5 | 8 | 49 | 6 | 3.7 | 5.5 | 9 | 38 | 22 | 31 | M5-16 | |||||

| 30 | 35 | (60) | 38 | 37.5 | 10 | 63 | 8 | 4.2 | 6.6 | 11 | 50 | 30 | 40 | M6-20 | ||||||

| 35 | +0.050 +0.025 | 50* | 44 | 43.5 | 69 | 56 | 36 | 43 | ||||||||||||

| 40 | 60 | 50 | 49.5 | 13 | 82 | 10 | 5.2 | 9 | 14 | 66 | 38 | 54 | M8-25 | |||||||

[ ! ]Precautions for use of Oil Free Bushings

·Recommended matching shaft for I.D. F7 type d8: General use (high load) f8: High accuracy use e7: General use (light load) g6: High accuracy use (intermittent operation)

·It is recommended to fix the bushing with anti-rotation screw.

[ M ] Material of Oil Free Bushings: High strength brass alloy

Embedded solid lubricant

[ A ] Accessories: Low head hexagon socket head screws 2 to 4 pcs

2. Can withstand greater heavy loads than ball bearings.

3. It can be used in ‘high’ and ‘low temperature’ temperature conditions.

4. Compared to ball bearings, the bush thickness is thinner and saves space.

5. Applicable to linear motion and rotary motion.

Feature 2: Best suited for use in heavy load and low speed driving conditions.

Feature 3: Excellent wear resistance in areas where oil film formation is difficult, such as reciprocating motion, frequent starting and stopping, etc.

■Precision positioning with 7 levels of inner diameter tolerance is more accurate

・Oil Free Bushings, Even the MISUMI economic type has the same inspection standards as MISUMI standard products, and quality inspection is performed before shipment from the factory. We provide products that are suitable for users. Specification valuefrom product catalog.

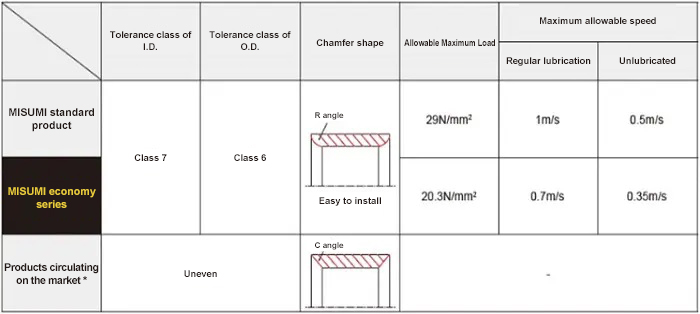

■ Comparison of specifications (take straight type as an example)

Easy installation

- When assembling, be careful that there are no foreign substances on the surface.

- After use, the sliding surface will become black or black due to the oil film formed by the solid lubricant, so do not rub and use it as usual.

- Applying lubricant to the grinding part before assembly can shorten the break-in period, which is advantageous for machine operation.

- During assembly, it should be pressed slowly, and knocking is strictly prohibited, so as not to damage the bearing and cause deformation.

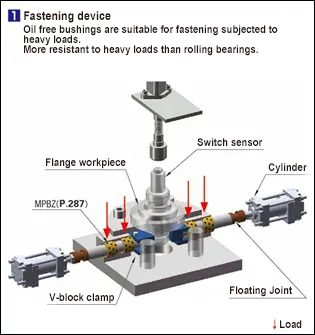

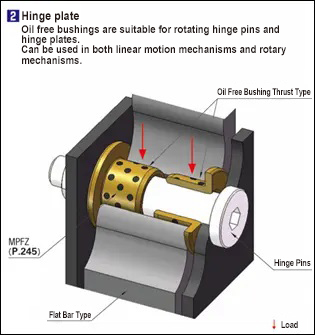

Use Cases of Oil Free Bushings

Caution of Oil Free Bushings

Model selection and precautions for use of Oil Free Bushings

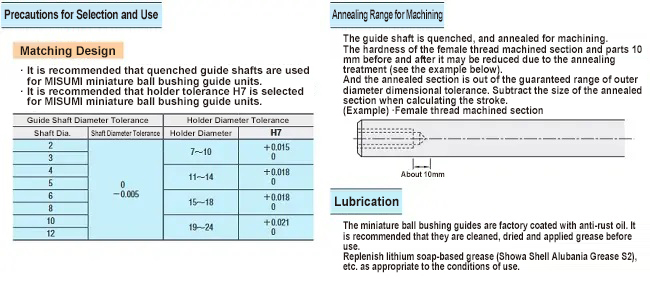

Combined design

- MISUMI miniature ball bush units are recommended to use heat-treated shafts.

- It is recommended to select the holder tolerance as H7 for Misumi miniature ball bushing units.

| Shaft diameter tolerance | Holder diameter tolerance | ||

| Measurement | Measurement Tolerance | Holder Diameter | H7 |

| 2 | 0 -0.005 | 7∼10 | +0.015 0 |

| 3 | |||

| 4 | 11∼14 | +0.018 0 | |

| 5 | |||

| 6 | 15∼18 | +0.018 0 | |

| 8 | |||

| 10 | 19∼24 | +0.021 0 | |

| 12 | |||

Machining heat treatment range of Oil Free Bushings

The shaft is heat-treated and then machined.Due to heat treatment, the hardness of the female screw machining part ± 10mm before and after may decrease (see example below).

In addition, the heat treatment area is not within the guaranteed range of the outer diameter dimensional tolerance.When calculating the stroke, subtract the dimensions of the heat treated part.

Lubrication of Oil Free Bushings

When shipping miniature ball bushings, anti-rust oil is applied. Please wash and dry them, then apply grease before use.

Depending on the usage environment, replenish lithium soap-based grease (such as Alubania Grease S2 made by Showa Shell Sekiyu) as needed.

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| E-MUITZ16-30 |

| E-MUIZ16-30 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Inner Dia. d (Ø) | Outer Dia. D (Ø) | Overall Length L (mm) | Dimension H (mm) | Width Across Flats (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

₹ 1,739.10 | 1 Piece(s) | Available | Same day | 10 | 16 | 22 | 30 | 40 | 28 | |

₹ 1,526.80 | 1 Piece(s) | Available | Same day | 10 | 16 | 22 | 30 | 40 | - |

Loading...

2. More resistant to heavy loads than rolling bearings.

3. Can be used under severe conditions of "high" and "low" temperatures.

4. Bushings are thin and space-saving, compared to rolling bearings.

5. Can be used for linear and rotary motions.

Feature 2: Ideal for use in heavy-duty and low-speed operating conditions.

Feature 3: Excellent wear resistance in areas where it is difficult to form an oil film, such as reciprocating movements and frequent starts and stops.

・Even for MISUMI economy series, the inspection standard is the same as that of MISUMI standard products, and factory inspection is carried out to provide users with products that meet the catalog specifications.

・R chamfer, which facilitates installation

・The standard load and operating speed of the catalog are ensured, so it can be used with peace of mind.

- When assembling, check that there are no foreign objects on the surface.

- The sliding surface may become black or grey-black after use due to the oil film formed by the solid lubricant. Do not scrub it and use as usual.

- Before assembly, if the lubricant is applied to the grinding parts, it can shorten the running-in period and facilitate the operation of the machine.

- When assembling, it should be pressed in slowly. Knocking is strictly prohibited to avoid damaging the bearings and causing deformation.

Basic Information

| Type | Flange Integrated | Metal Type | High-Tensile Brass Alloy | Environment | Standard / In Oil |

|---|---|---|---|---|---|

| Mounting Shaft Fits | d8 / e7 / g6 / f8 | Lubrication | Unlubricated / Regular Lubrication | Max. Allowable Surface Pressure P(N/mm2) | 29 |

| Maximum Allowable Velocity(m/s) | 0.5 | Max. Allowable PV Value Range(N/mm2•m/s) | 1.1~2.0 | Max. Allowable PV Value(N/mm2•m/s) | 1.65 |

| Operating Temperature Range(°C) | -40::150 | Type | Embedded Flanged Type |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: What are oil free bushings and what are their features?

- Answer: Plain bearings where the body of the bushing is saturated with lubricant and can be used "without oil" or "with a reduced oil supply". < br / >Oil free bushings have the following features: < br / > 1. Low maintenance frequency; < br / > 2. Suitable for low speed and heavy load situations, compared with ball linear bearings; < br / > 3. Can also be used under harsh conditions of high temperature and low temperature; < br / > 4. Thinner and space saving, compared with linear bearings; < br / > 5. Can be used for both linear and rotational motions.

- Question: What are the materials and features of MISUMI oil free bushings?

-

Answer:

MISUMI oil free bushings are available in 5 types, i.e. copper alloy, bronze casting, dry, resin, and casting.

Copper alloy (metal type), excellent resistance to high temperature, chemicals and shock, suitable for heavy duty and low speed operation.

Bronze casting (metal type) with excellent sinter resistance, enabling slight movements, suitable for low load and high speed operation.

Dry type (composite layer type), high temperature resistant, suitable for heavy duty and low speed operation, thin-walled and compact.

Resin (resin type), high temperature and chemical resistant (tetrafluoroethylene resin), complying with food sanitation law, suitable for low load and low speed operation.

Castings (metal type), suitable for medium load and low speed operation.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy