(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 24/11/2024 to 4:30 (IST) 25/11/2024. We apologize for the inconvenience.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Specification/Dimensions

-

Plate Thickness T(mm)

-

Width B(mm)

-

Length A(mm)

-

Tolerance Selection

- Not specified

- P

-

Type

- Hole machining type

- Standard type

-

Number of Holes

- 2H (2 holes)

- 4H (4 holes)

-

Counterbored Hole (Nominal Bolt Dia.) [Z]

-

Through Hole (Nominal Bolt Dia.) [N]

-

F(mm)

-

G(mm)

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 14 Day(s) or Less

Specify Alterations

High Strength, Normal Grade, Heat Resistance Within 220 °C

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Description

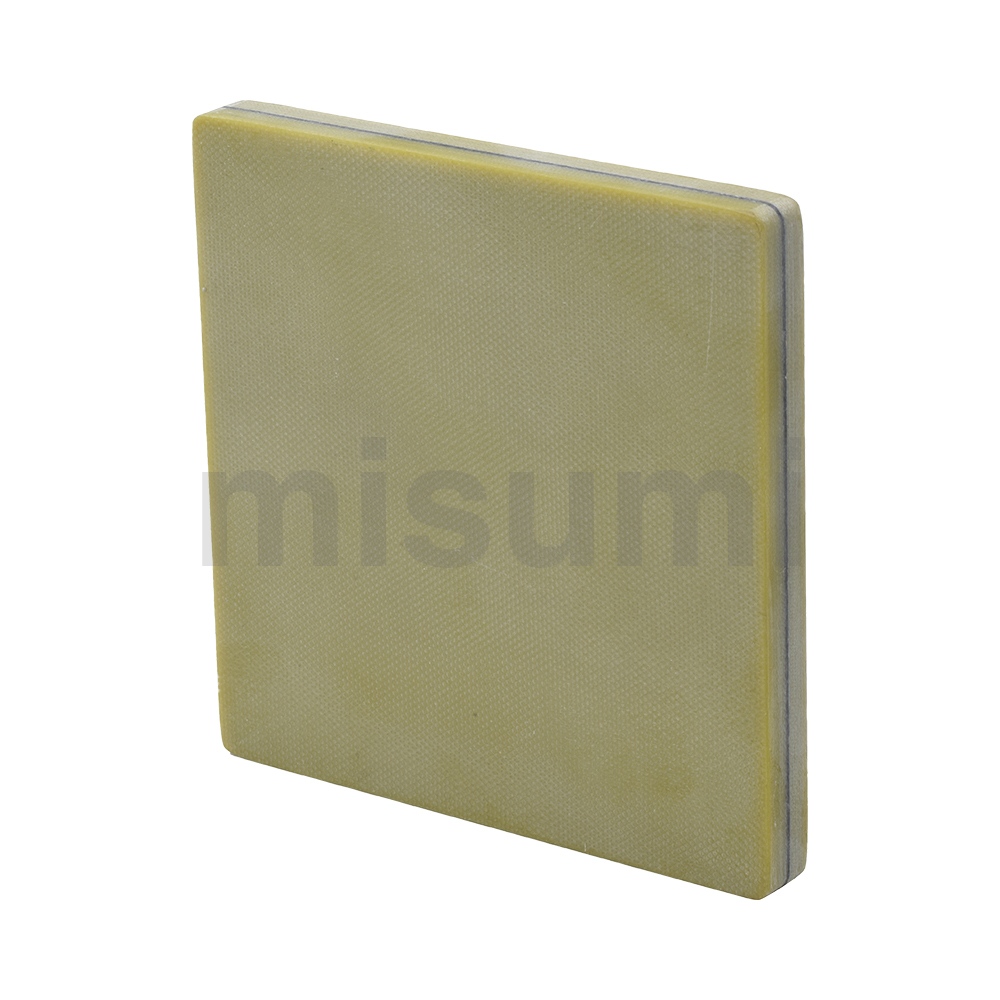

High Strength, Normal Grade, Heat Resistance Within 220 °C

Heat Insulating Plates are an economy item, The price is cheaper than the MISUMI standard product. They offer a wide variety of sizes to choose from.

[Feature]

● Plate Thickness Minimum/Maximum (mm.): 3 and 30

● Width and Length (mm.) : Can configurable between 20 to 800 mm, and the minimum length can be increased by increments 1 mm.

● Operating Environment Temperature (℃) : Normal temperature~220

● Main Material : Epoxy-modified resin

[Application]

It is used for thermal insulation of connecting parts and thermal insulation of flanges

Economy Heat Insulating Plates

- High strength with excellent thermal insulation at high temperatures

- Made from epoxy-modified resin and fiberglass cloth

- Available in customizable sizes within specified range

- Ideal for use in high-temperature environments

- Multiple configurations with or without hole machining

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product of Heat Insulating Plates Overview

It plays a great role in preventing heat diffusion, improving energy efficiency, distributing heat evenly, protecting peripheral components such as bearings and sensors, inhibiting heat deformation, etc.

Product of Heat Insulating Plates Features

Feature 2: The high-strength grade Heat Insulating Plates has high compressive strength and bending strength, so it is ideal for applications that require high strength.

Feature 3: The high temperature-resistant Heat Insulating Plates has small high-temperature expansion. It has compressive strength that hardly deteriorates at high temperature, exhibits less deformation under pressure, and maintains dimensional stability for a long time at high temperature.

Feature 4: The standard type and hole machining type are available to satisfy your needs.

Feature 5: The Heat Insulating Plates products are provided in a rich variety to meet different requirements on high temperature and thermal conductivity.

Feature 6: Due to excellent heat insulation effect, each product is dimensionally stable without deformation when heated within the operating temperature range.

Dimensional Drawing of Heat Insulating Plates

A≥B

A≥BSpecifications of Heat Insulating Plates Overview

| Type | Dimension tolerance of A·B | Main Substrate | Main Material | Grade | Color | Recommended Operating Environment Temperature |

| Temperature Insulating Super Insulating Grade | Unspecified P | Fiberglass cloth | Epoxy-modified resin | High strength type | Green | Normal temperature~220℃ |

For more information on product features, please see

For more information on product features, please see  Features of Heat Insulating Plates.

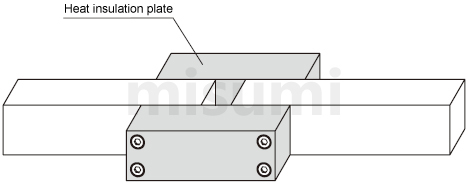

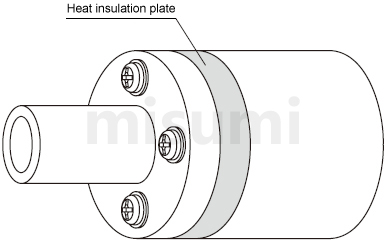

Features of Heat Insulating Plates.Example of Heat Insulating Plates Use

| Example of Heat Insulating Plates Use ① | Role of Heat Insulating Plates Product |

| Used for thermal insulation of connecting parts |

| Example of Heat Insulating Plates Use ② | Role of Heat Insulating Plates Product |

| Used for thermal insulation of flanges |

Precautions for Using Heat Insulating Plates

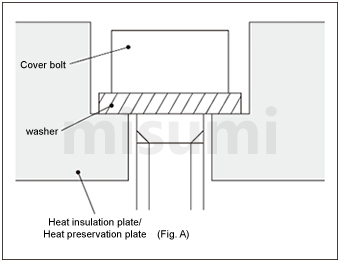

・Make sure to use bolts with washers, otherwise it may cause breakage due to excessive tightening. (Figure A)

・Do not use it in the environment containing moisture and drugs. Heat insulating plates containing moisture may crack or deteriorate significantly in performance with increasing temperature.

・ Because it is a laminating molded product, do not apply any force in the lamination direction (splitting direction) during use.

・ When used at a certain heating temperature, it may produce slight smell, which is not harmful, but please take ventilation measures and dispose of the smell as general smoke, keeping your face at a safe distance.

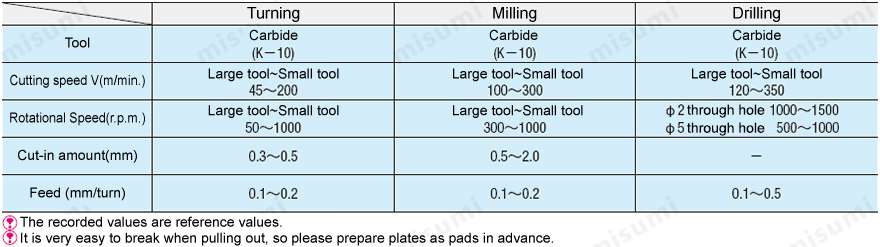

② Precautions for machining Heat Insulating Plates:

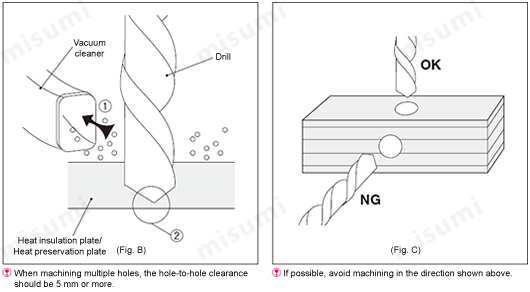

・During machining, please collect dust with a vacuum cleaner to avoid dust scattering. (Figure B)

Although it does not contain specific chemicals, such as asbestos, conventional dust operation safety measures such as wearing masks and protective glasses must be taken.

In addition, because it contains glass fibers, it may cause skin itching. It is recommended to wear gloves during operation. If sliding parts of other processing machines are covered with dust, the mechanical accuracy may deteriorate due to wear and tear.

・ When drilling and other hole opening operations are carried out, it may break, so you have to pay attention to the hole spacing, hole diameter and processing conditions.

・ The laminating molded product is not suitable for thread machining, three-dimensional machining, etc. Such machining operations as drilling and cutting in the lamination direction are main causes of cracking, so please avoid such operations whenever possible. (Figure C)

■ Recommended Heat Insulating Plates machining conditions

Related Industries of Heat Insulating Plates

Related Documents of Heat Insulating Plates

Here

Here Precautions for use of heat insulating plate Click

Here

HereRelated Products of Heat Insulating Plates

| Resin Washer Standard Type Single Product/Sold in Bags | Stopper bolt with urethane Straight type | Resin Collar Standard | ||

|  |  | ||

| Typical model: PACK-WSJJ4-2-2 | Typical model: UST8-40 | Typical model: CLJJ10-16-20.0 | ||

| Advantages: Single and packed products are available, with packed ones sold at more favorable prices. | Suitable for conveying heavy load workpieces, compact tip, usable in narrow spaces | Advantages: Optional inner and outer diameter and height, better price |

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| E-HIPLB2H-[20-800/1]-[5,15]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[5-795/0.5]-N[3,4,5,6,8,10] |

| E-HIPLB2H-[20-800/1]-[5,15]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[5-795/0.5]-Z[4,5,6,8] |

| E-HIPLB2H-[20-800/1]-[20-800/1]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[5-795/0.5]-N[3,4,5,6,8,10] |

| E-HIPLB2H-[20-800/1]-[20-800/1]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[5-795/0.5]-Z[4,5,6,8] |

| E-HIPLB4H-[20-800/1]-[5,15]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[9-791/0.5]-N[3,4,5,6,8,10] |

| E-HIPLB4H-[20-800/1]-[5,15]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[9-791/0.5]-Z[4,5,6,8] |

| E-HIPLB4H-[20-800/1]-[20-800/1]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[9-791/0.5]-N[3,4,5,6,8,10] |

| E-HIPLB4H-[20-800/1]-[20-800/1]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[9-791/0.5]-Z[4,5,6,8] |

| E-HIPLB-[20-800/1]-[20-800/1]-[3,5,10,15,20,25,30] |

| E-HIPLBP2H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP2H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPLBP2H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-G[5-195/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP2H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-G[5-195/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPLBP2H-[20-200/1]-[5,10]-F[9-191/0.5]-F[9-191/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP2H-[20-200/1]-[5,10]-F[9-191/0.5]-F[9-191/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPLBP2H-[20-200/1]-[5,10]-F[9-191/0.5]-G[5-195/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP2H-[20-200/1]-[5,10]-F[9-191/0.5]-G[5-195/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPLBP2H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP2H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPLBP2H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-G[5-195/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP2H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-G[5-195/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPLBP2H-[20-200/1]-[20-200/1]-F[9-191/0.5]-F[9-191/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP2H-[20-200/1]-[20-200/1]-F[9-191/0.5]-F[9-191/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPLBP2H-[20-200/1]-[20-200/1]-F[9-191/0.5]-G[5-195/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP2H-[20-200/1]-[20-200/1]-F[9-191/0.5]-G[5-195/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPLBP4H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP4H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPLBP4H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-G[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP4H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-G[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPLBP4H-[20-200/1]-[5,10]-F[9-191/0.5]-F[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP4H-[20-200/1]-[5,10]-F[9-191/0.5]-F[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPLBP4H-[20-200/1]-[5,10]-F[9-191/0.5]-G[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP4H-[20-200/1]-[5,10]-F[9-191/0.5]-G[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPLBP4H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP4H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPLBP4H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-G[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP4H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-G[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPLBP4H-[20-200/1]-[20-200/1]-F[9-191/0.5]-F[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP4H-[20-200/1]-[20-200/1]-F[9-191/0.5]-F[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPLBP4H-[20-200/1]-[20-200/1]-F[9-191/0.5]-G[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPLBP4H-[20-200/1]-[20-200/1]-F[9-191/0.5]-G[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPLBP-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Plate Thickness T (mm) | Width B (mm) | Length A (mm) | Tolerance Selection | Type | Number of Holes | Counterbored Hole (Nominal Bolt Dia.) [Z] | Through Hole (Nominal Bolt Dia.) [N] | F (mm) | G (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 800 | Not specified | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 791 | 5 ~ 795 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 800 | Not specified | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 791 | 5 ~ 795 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 800 | 20 ~ 800 | Not specified | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 791 | 5 ~ 795 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 800 | 20 ~ 800 | Not specified | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 791 | 5 ~ 795 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 800 | Not specified | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 791 | 9 ~ 791 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 800 | Not specified | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 791 | 9 ~ 791 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 800 | 20 ~ 800 | Not specified | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 791 | 9 ~ 791 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 800 | 20 ~ 800 | Not specified | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 791 | 9 ~ 791 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 800 | 20 ~ 800 | Not specified | Standard type | - | - | - | - | - | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | - | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | - | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | - | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | - | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | - | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | - | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | - | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | - | 5 ~ 195 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | - | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | - | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | - | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | - | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | - | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | - | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | - | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | - | 9 ~ 191 | ||

- | 1 Piece(s) | 14 Day(s) | 10 | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Standard type | - | - | - | - | - |

Loading...

A≥B

A≥B| Type | Dimension tolerance of A·B | Main Substrate | Main Material | Grade | Color | Recommended Operating Environment Temperature |

| Temperature Insulating Super Insulating Grade | Unspecified P | Fiberglass cloth | Epoxy-modified resin | High strength type | Green | Normal temperature~220℃ |

Dimension Specification Table

■Standard Type

| Part Number | 1mm increments | Selection T T | ||

Type Type | Tolerance Selection |  A A |  B B | |

| A≥B | ||||

| Temperature Insulating Super Insulating Grade | Unspecified (+1.0, 0) P (±0.3) | 20 to 800 | 20 to 800 | 3 5 10 15 20 25 30 |

| 20~200 | 20 to 200 | |||

■Hole machining type

| Part Number | 1mm increments | Selection T T | 0.5mm increments |  Bolt Nominal Diameter Selection Bolt Nominal Diameter Selection | |||||

Type Type | Tolerance Selection |  Number of Holes Number of Holes |  A A |  B B |  F F |  G G | N | Z | |

| A≥B | |||||||||

| Temperature Insulating Super Insulating Grade | Unspecified (+1.0, 0) | 2H 4H | 20~800 | 20 to 800 | 3 | 9~791 | 5 to 795 (2H) 9 to 791 (4H) | 3 4 5 6 8 10 | - |

| 5 | - | ||||||||

| 10 | 4 5 6 | ||||||||

| 15 | 4 5 6 8 | ||||||||

| 20 | 4 5 6 8 | ||||||||

| 25 | 4 5 6 8 | ||||||||

| 30 | 4 5 6 8 | ||||||||

| P (±0.3) | 20~200 | 20 to 200 | 3 | 9~191 | 5 to 195 (2H) 9 to 191 (4H) | - | |||

| 5 | - | ||||||||

| 10 | 4 5 6 | ||||||||

| 15 | 4 5 6 8 | ||||||||

| 20 | 4 5 6 8 | ||||||||

| 25 | 4 5 6 8 | ||||||||

| 30 | 4 5 6 8 | ||||||||

The specified range of Dimension F must satisfy: d(d1)+5≤F≤A-d(d1)-5.

The specified range of Dimension F must satisfy: d(d1)+5≤F≤A-d(d1)-5. When selecting the 2H type, the specified range of Dimension G must satisfy: d(d1)/2+2.5≤G≤B-d(d1)/2-2.5. When selecting the 4H type, it must satisfy: d(d1)+5≤G≤B-d(d1)-5. (When selecting d for through hole and d1 for counterbored hole)

When selecting the 2H type, the specified range of Dimension G must satisfy: d(d1)/2+2.5≤G≤B-d(d1)/2-2.5. When selecting the 4H type, it must satisfy: d(d1)+5≤G≤B-d(d1)-5. (When selecting d for through hole and d1 for counterbored hole) When selecting the machining type with hole, please select N (through hole) and Z (counterbored hole).

When selecting the machining type with hole, please select N (through hole) and Z (counterbored hole).| Hole Machining Detail | |||||||||||||||||||||||||||||||||

| N (Through hole) | Z (Counterbored Hole) | ||||||||||||||||||||||||||||||||

|  | ||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||

Basic Information

| Recommended Operating Temperature(°C) | Room Temp. ~ 220 | Grade | Temperature Insulating Super Insulating Grade | Color | Green |

|---|---|---|---|---|---|

| Thermal Conductivity(W/m·K) | 0.23 | Expansion Rate(℃-1) | 0.000059 | Main Base Material | Glass Fiber Cloth |

| Main Material | Epoxy Modified Resin |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: What is the reason for the poor heat insulation effect of the purchased heat insulation plate?

- Answer: The heat insulation effect of the heat insulation plate is related to the thermal conductivity and the plate thickness. The lower the thermal conductivity, the greater the thickness, the better the heat insulation effect. It is also related to the working condition (if applicable) of the heat insulation plate used.

- Question: Is the operating temperature of the heat insulation plate the guaranteed value?

- Answer: The operating temperature of the heat insulation plate is the recommended operating temperature, which refers to the temperature where the quality will not drop sharply after a certain period of long-term use.

- Question: Is it possible to purchase MISUMI heat insulation plate and then make alterations by oneself?

- Answer: Yes. However, be sure to refer to the processing precautions and heat insulation plate processing conditions in the precautions. In addition, it is recommended that the hole should be at least 5mm thick from the edge of the material.

- Question: Is there a big difference between the materials of economy series heat insulation plate and imported heat insulation plate?

- Answer: The economy series heat insulation plate is made of domestically produced materials with fully evaluated performance and close to the quality of imported heat insulation plate, but more cost-effective.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy