(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Specification/Dimensions

-

Lead Wire Length (F)(m)

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

Specify Alterations

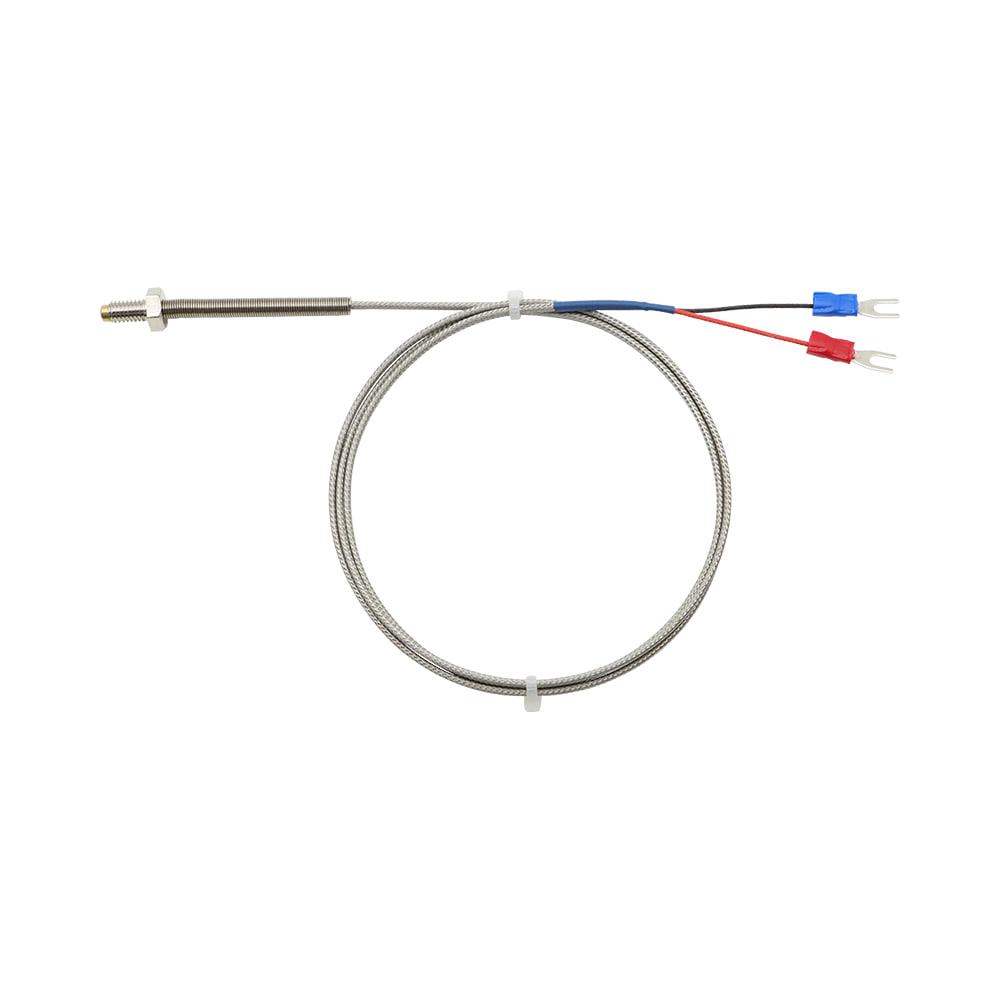

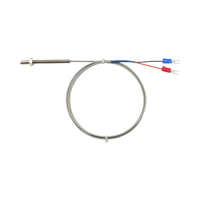

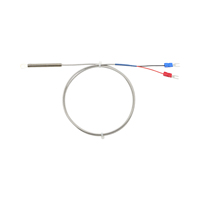

Temperature Sensors Screw Mount K-Thermocouple

- Volume Discount

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Description

Temperature Sensors Screw Mount K-Thermocouple

These Temperature Sensors Thermocouple type K are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Temperature Sensors : Thermocouple Type K

● Screw Size: M6 X 1.0

● Wire Length (m.): 1, 2, and 5

● Temperature Range (°C) : 0-300

● Crimp Terminal Type: Y-Shaped 2 sets

[Application]

It is used in a variety of application such as heat treatment, packaging industry , plastic industry , and so on.

Economy Thermocouple Screw Mount

- Convenient M6 x 1.0 screw mount. Ensures easy and secure installation, enhancing stability and reliability in temperature measurements.

- Available in multiple wire lengths.

- High sensitivity to temperature variations. Provides accurate and reliable data, critical for maintaining process quality and consistency.

- Suitable for various industries. Used in heat treatment, packaging, plastics, and more, demonstrating its versatility and broad applicability.

- Standard Y-shaped crimp terminals. Simplifies connection with existing systems, ensuring hassle-free integration and improved efficiency.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Temperature Sensors Dimensional Drawing

Temperature Sensors For more information on product dimensional drawings, please refer to the product catalog.

Temperature Sensors Specification Table

| Temperature Sensors Type | F (m) | Screw Size | Shape | Temperature Range |

| C-MSNDM6 | 1 | M6×1.0 | K type thermocouples | 0 to 300℃ |

| 2 | ||||

| 5 |

Temperature Sensors Product Overview

The thermocouple consists of two wires made of different materials, which are welded together at the end. After the ambient temperature of the unheated part is measured, the temperature of the heating point can be accurately known. Because it must have the conductor made of two different materials, it is called the thermocouple. The thermocouples made of different materials can be used in different temperature ranges, and their sensitivities are different from each other. The sensitivity of a thermocouple refers to the change in the output potential difference when the temperature of the heating point changes by 1°C. For most metal-supported thermocouples, this value is between 5-40 µV/°C.

PT100

Pt100 is a platinum thermal resistance, and its resistance value is proportional to the change of temperature. 100 after PT means that its resistance value is 100 ohms at 0°C and about 138.5 ohms at 100°C.

Temperature Sensors Product Feature

Temperature Sensors Related Products

|  |  |  |

| High-temperature thermocouples | Screw-mounting thermocouples | Screw mount bendable PT100 | Round terminal thermocouples |

Temperature Sensors Precautions

Temperature Sensors Precautions for use

Temperature Sensors Precautions for use To extend the thermocouple lead wire, please use the compensation lead wire.

To extend the thermocouple lead wire, please use the compensation lead wire. Please strictly observe the heat resistant Temperature Sensors of each part in product page. Please note that even the upper limit of the temperature measurement is very high, malfunctions such as wire breakage may occur if the heat-resistant temperature is exceeded.

Please strictly observe the heat resistant Temperature Sensors of each part in product page. Please note that even the upper limit of the temperature measurement is very high, malfunctions such as wire breakage may occur if the heat-resistant temperature is exceeded. Do not apply large external force or vibration.

Do not apply large external force or vibration. Please note the heat resistance Temperature Sensors of the sleeve part.

Please note the heat resistance Temperature Sensors of the sleeve part. Please keep the upper limit of the temperature below the temperature measurement range of the product. If the bushing temperature exceeds the heat-resistant temperature, it is very easy to cause the breakage of the temperature measurement wire.

Please keep the upper limit of the temperature below the temperature measurement range of the product. If the bushing temperature exceeds the heat-resistant temperature, it is very easy to cause the breakage of the temperature measurement wire. If the temperature of heat generating parts exceeds 100°C, please choose the specification with a front end as long as possible.

If the temperature of heat generating parts exceeds 100°C, please choose the specification with a front end as long as possible.

Temperature Sensors Usage Method

Temperature Sensors Brand introduction

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| C-MSNDM6-1 |

| C-MSNDM6-2 |

| C-MSNDM6-5 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Lead Wire Length (F) (m) |

|---|---|---|---|---|---|---|

₹ 1,061.00 | 1 Piece(s) | Available | Same day | 10 | 1 | |

₹ 1,179.00 | 1 Piece(s) | Available | Same day | 10 | 2 | |

₹ 1,198.54 | 1 Piece(s) | Available | Same day | 10 | 5 |

Loading...

For more information on product dimensional drawings, please refer to the product catalog.

| Type | F (m) | Screw Size | Shape | Temperature Range |

| C-MSNDM6 | 1 | M6×1.0 | K type thermocouples | 0 to 300℃ |

| 2 | ||||

| 5 |

Basic Information

| Type of Temperature Sensor | Thermocouple | Type of Thermocouple | K Thermocouple | Sheath, Protection Tube Diameter(Ø) | 4.3 |

|---|---|---|---|---|---|

| Measurement Object | Temperature Sensor | Temperature Measurement Contact Point | Grounded Type | Operating Temperature Range(°C) | 0::300 |

| Sheath, Protecting Tube's Thread Nominal | M6 |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: What are the main types of sensors currently sold by MISUMI?

- Answer: Photoelectric sensors, proximity sensors, pressure sensors, temperature sensors, etc.

- Question: What is a photo microsensors?

- Answer: With an amplifier, an emitter and a receiver built in its integrated main body, it is a sensor that is easy to install and adjust, usually designed for detecting the passage of workpieces on the conveying line and for positioning workpieces, etc.

- Question: What are the features of the photoelectric sensor?

-

Answer:

1. The action (response time) is very fast because light is used as the medium.

2. It has a longer detection distance than the light sensor and allows for remote detection.

3. Objects made of almost any material can be detected as long as they reflect light. - Question: What are the detection methods of the photoelectric sensor?

- Answer: Transmittance type, regression reflection type, diffusion reflection type, limited reflection type, etc.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy