(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 24/11/2024 to 4:30 (IST) 25/11/2024. We apologize for the inconvenience.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Specification/Dimensions

-

Shaft Bore Dia. d(mm)

-

type

- C-DRC06B

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 12 Day(s) or Less

Specify Alterations

Idler Sprocket European Standard Single Bearing

- Volume Discount

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Overview

■Sprocket idler is a sprocket with a built-in bearing. Its main function is to change the rotating direction of the driven wheel, tension the chain, adjust the pressure angle and so on.

The idler is a part of the gear train that plays a transitional role. It does not change the transmission relationship. It is to make the force of the gear train more reasonable or to adapt to the layout of the entire transmission system.

■Only sprockets and chains with the same specifications can be used in combination.

This series is ISO standard 04B/ 05B/ 06B/ 08B/ 10B/ 12B/ 16B sprocket idlers.

Do not use them with 04C/ 06C/ 08A/ 10A/12A/16A series (ANSI specifications 25B/ 35B/ 40B/50B/60B/80B) sprockets and chains, which may cause the chain sprocket mechanism to fail to operate normally!

The idler is a part of the gear train that plays a transitional role. It does not change the transmission relationship. It is to make the force of the gear train more reasonable or to adapt to the layout of the entire transmission system.

■Only sprockets and chains with the same specifications can be used in combination.

This series is ISO standard 04B/ 05B/ 06B/ 08B/ 10B/ 12B/ 16B sprocket idlers.

Do not use them with 04C/ 06C/ 08A/ 10A/12A/16A series (ANSI specifications 25B/ 35B/ 40B/50B/60B/80B) sprockets and chains, which may cause the chain sprocket mechanism to fail to operate normally!

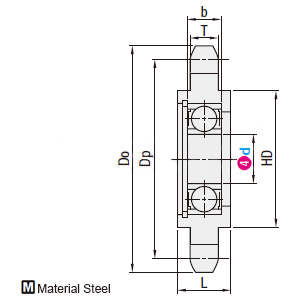

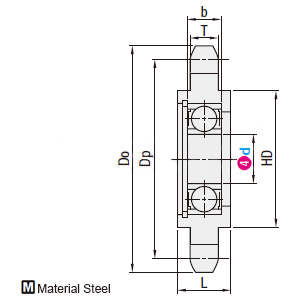

Dimensional Drawing

Ordinary ISO standard 04B/ 05B/ 06B/ 08B/ 10B/ 12B/ 16B series sprocket idlers,

Specifications Overview

Features: tension is applied to the chain, preventing the chain vibration, noise and poor engagement of the sprocket.

This series is ISO standard 04C/ 06C/ 08A/ 10A/12A/16A (ANSI specifications 25B/ 35B/40B/50B/60B/80B) sprocket idlers, which can be used with our 25/ 35/40/50/60 /80 chains

■Do not use them with 08B/ 10B/ 12B/ 16B series chains, which may cause the chain sprocket mechanism to fail to operate normally!

This series is ISO standard 04C/ 06C/ 08A/ 10A/12A/16A (ANSI specifications 25B/ 35B/40B/50B/60B/80B) sprocket idlers, which can be used with our 25/ 35/40/50/60 /80 chains

■Do not use them with 08B/ 10B/ 12B/ 16B series chains, which may cause the chain sprocket mechanism to fail to operate normally!

| Part Number |  Number of Teeth Number of Teeth |  d d | Dp | Do | T | HD | L | Bearing | Applicable size of idler pin | Approximate weight (kg) | ||||

Type Type |  No. No. | Part No. | b | Cr (dynamic rated load) kN | Single liner type bearing | DRC | ||||||||

| Steel | ||||||||||||||

| Single bearing C-DRC | 06B | 16 | 10 | 48.82 | 54 | 5.3 | 38 | 14 | 6000ZZ | 8 | 4.55 | IDP6000S | 0.11 | |

| 12 | 6001ZZ | 8 | 5.1 | IDP6001S | 0.1 | |||||||||

| 18 | 15 | 54.85 | 60 | 44 | 17 | 6203ZZ | 11 | 7.65 | IDP6202S | 0.16 | ||||

| 25 | 20 | 76 | 81 | 60 | 21 | 6204ZZ | 14 | 12.8 | IDP6204S | 0.33 | ||||

| 08B | 13 | 10 | 53.07 | 59 | 7.2 | 38 | 14 | 6000ZZ | 8 | 4.55 | IDP6000S | 0.15 | ||

| 12 | 6001ZZ | 8 | 5.1 | IDP6001S | 0.14 | |||||||||

| 15 | 15 | 61.08 | 67 | 44 | 17 | 6202ZZ | 11 | 7.65 | IDP6202S | 0.19 | ||||

Product Feature

■Sprocket chain drive has the following features compared with gear drive and belt drive:

1. Multi-tooth load bearing, safe and reliable;

2. Flexible transmission, absorbing shock and vibration;

3. Large center distance range, low manufacturing and mounting accuracy requirements;

4. Compared with belt drive, the transmission ratio is accurate and the transmission efficiency is higher, suitable for high temperature.

■Two main purposes of the chain:

1. Connect the motor for transmission 2. Place the workpiece directly or indirectly on the chain for transfer

1. Multi-tooth load bearing, safe and reliable;

2. Flexible transmission, absorbing shock and vibration;

3. Large center distance range, low manufacturing and mounting accuracy requirements;

4. Compared with belt drive, the transmission ratio is accurate and the transmission efficiency is higher, suitable for high temperature.

■Two main purposes of the chain:

1. Connect the motor for transmission 2. Place the workpiece directly or indirectly on the chain for transfer

Example of Use

Used for driving power

A mechanism that can convert motor power into roller rotation by combining multiple sprockets and chains

A mechanism that can convert motor power into roller rotation by combining multiple sprockets and chains

Used for transporting workpieces

A chain conveyor frame with high versatility using flat profiles and chain guides

A chain conveyor frame with high versatility using flat profiles and chain guides

Used for transporting workpieces

A mechanism used to mount accessories on the chain, and extract and transport workpieces

A mechanism used to mount accessories on the chain, and extract and transport workpieces

Precautions

Usage Method

How to mount the roller chain

(A) Axis configuration

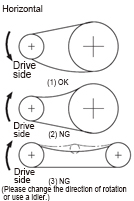

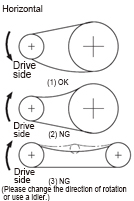

■Horizontal

Even when the two axes are arranged horizontally, the rotation direction of the axis must be considered.

The examples (2) and (3) in the figure show that when the chain is stretched, the disengagement between the sprocket teeth and the chain is not smooth and may bite.

In particular, the upper and lower chains in (3) will contact each other, so an idler is required.

■Horizontal

Even when the two axes are arranged horizontally, the rotation direction of the axis must be considered.

The examples (2) and (3) in the figure show that when the chain is stretched, the disengagement between the sprocket teeth and the chain is not smooth and may bite.

In particular, the upper and lower chains in (3) will contact each other, so an idler is required.

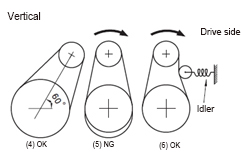

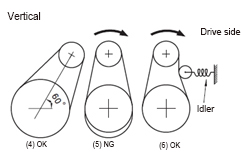

■Vertical

If the chain is stretched, slack as shown in (5) will occur, and

when a small sprocket is used on the lower side, the chain may fall off. Therefore, please use it at an angle of 60 or less as shown in (4).

When it is necessary to use it vertically due to the mechanism or space, it is recommended to put the large sprocket on the lower side, and

use the idler on the outside or inside as shown in (6).

If the chain is stretched, slack as shown in (5) will occur, and

when a small sprocket is used on the lower side, the chain may fall off. Therefore, please use it at an angle of 60 or less as shown in (4).

When it is necessary to use it vertically due to the mechanism or space, it is recommended to put the large sprocket on the lower side, and

use the idler on the outside or inside as shown in (6).

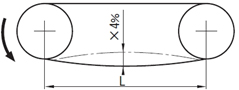

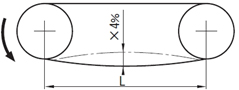

(B) Deflection

Deflection is generally about 4% of the shaft spacing, and about 2% in the following cases.

a. Vertical transmission or close to vertical transmission

b. Shaft spacing is more than 1m

c. When frequent heavy load starting and stopping are required

d. When reverse rotation is required

Deflection is generally about 4% of the shaft spacing, and about 2% in the following cases.

a. Vertical transmission or close to vertical transmission

b. Shaft spacing is more than 1m

c. When frequent heavy load starting and stopping are required

d. When reverse rotation is required

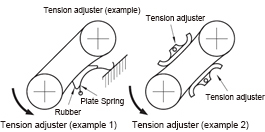

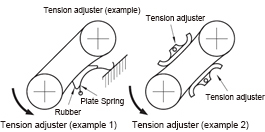

(C)When the load changes

If a tension adjuster is mounted on the tension side or slack side of the chain to provide initial tension in advance, it will eliminate vibration and reduce noise during operation.

If a tension adjuster is mounted on the tension side or slack side of the chain to provide initial tension in advance, it will eliminate vibration and reduce noise during operation.

Related Products

|

| Sprocket 60B |

Specification Table

Features: tension is applied to the chain, preventing the chain vibration, noise and poor engagement of the sprocket.

This series is ISO standard 04B/ 05B/ 06B/ 08B/ 10B/ 12B/ 16B sprocket idlers.

Do not use them with 04C/ 06C/ 08A/ 10A/12A/16A series (ANSI specifications 25B/ 35B/ 40B/50B/60B/80B) sprockets and chains, which may cause the chain sprocket mechanism to fail to operate normally!

Do not use them with 04C/ 06C/ 08A/ 10A/12A/16A series (ANSI specifications 25B/ 35B/ 40B/50B/60B/80B) sprockets and chains, which may cause the chain sprocket mechanism to fail to operate normally!

| Part Number |  Number of Teeth Number of Teeth |  d d | Dp | Do | T | HD | L | Bearing | Applicable size of idler pin | Approximate weight (kg) | ||||

Type Type |  No. No. | Part No. | b | Cr (dynamic rated load) kN | Single liner type bearing | DRC | ||||||||

| Steel | ||||||||||||||

| Single bearing C-DRC | 06B | 16 | 10 | 48.82 | 54 | 5.3 | 38 | 14 | 6000ZZ | 8 | 4.55 | IDP6000S | 0.11 | |

| 12 | 6001ZZ | 8 | 5.1 | IDP6001S | 0.1 | |||||||||

| 18 | 15 | 54.85 | 60 | 44 | 17 | 6203ZZ | 11 | 7.65 | IDP6202S | 0.16 | ||||

| 25 | 20 | 76 | 81 | 60 | 21 | 6204ZZ | 14 | 12.8 | IDP6204S | 0.33 | ||||

| 08B | 13 | 10 | 53.07 | 59 | 7.2 | 38 | 14 | 6000ZZ | 8 | 4.55 | IDP6000S | 0.15 | ||

| 12 | 6001ZZ | 8 | 5.1 | IDP6001S | 0.14 | |||||||||

| 15 | 15 | 61.08 | 67 | 44 | 17 | 6202ZZ | 11 | 7.65 | IDP6202S | 0.19 | ||||

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

Loading...

| Part Number |

|---|

| C-DRC06B-25-17 |

| C-DRC06B-25-20 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Shaft Bore Dia. d (mm) |

|---|---|---|---|---|---|---|

₹ 1,227.00 | 1 Piece(s) | Available | 12 Day(s) | 10 | 17 | |

₹ 1,227.00 | 2 Piece(s) | Available | 12 Day(s) | 10 | 20 |

Loading...

Basic Information

| Type | Idlers | Nominal | 06 | Number of Teeth(T) | 25 |

|---|---|---|---|---|---|

| Number of Strands | 1 | Material | Steel | Chain Type | RS |

| Shaft Type | Bearing Built-in, Single | Surface Treatment | Black Oxide |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: In chain drive, where is the tensioning wheel usually installed?

- Answer: Install the tensioning wheel on the inside of the loose edge of the belt close to the large pulley. It is often used when the center distance is not adjustable. The tensioning wheel is automatically pressed on the outside of the loose side of the belt close to the small wheel by using the suspending weight. It is used for applications where the transmission ratio is large and the center distance is small.

- Question: Does the chain need routine maintenance after installation and use?

- Answer: The chain needs regular maintenance after installation and use. These include daily lubricant application, confirmation of chain slack. The quality of lubrication will affect the life of the chain. Especially in recent years, high-speed use has been increasing, so it is necessary to take efficient lubrication methods.

- Question: How to use the carrier chain?

- Answer: The carrier chain can only be used for transmission, not for scenarios with large load and high positioning accuracy, please be careful!

- Question: Can the chain be cut off when it is extended?

- Answer: It can be cut off. Our company has simple chain cutter available for selection.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy